This marshmallow production line is a continuous aeration production equipment, which is delivered in full sets from raw material boiling to drying and packaging.

The equipment can be made into single color, multi-color, twisted flowers, cartoons, ice cream, fruity fillings, etc.

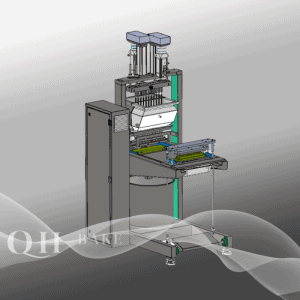

Equipment process flow:

Gelatin melting → Dissolve sugar → Aerate → CFA → Spread starch → Forming→ De-starch → Aging →Automatic Dry → Packaging

| Model | Capacity (kg/h) | Extrude nozzles | Depositing Nozzles | Steam require | Electric power | Length |

|---|---|---|---|---|---|---|

| 450mm | 50kg/h | 4-6 | / | 100kg | 30kW | 25m |

| 600mm | 60~100 | 6 | 16 | 100kg | 35kW | 30m |

| 900mm | 150-200 | 9 | 26 | 150kg | 45kW | 35m |

| 1200mm | 300-500 | 16 | 44 | 200kg | 55kW | 40m |

Key Features and Benefits

Continuous Aeration System

The automatic marshmallow production line is designed for continuous aeration, ensuring a light and fluffy texture in the final product. This system is delivered as a complete package, from raw material boiling to drying and packaging.

Versatile Production Capabilities

- Single-Color Marshmallows: Produces uniform, single-color marshmallows efficiently.

- Multi-Color and Twisted Shapes: Capable of creating multi-color and twisted marshmallows, adding visual appeal and variety.

- Custom Shapes: Can produce marshmallows in various shapes such as cartoon figures, ice cream, and fruit fillings by adjusting formulas and replacing molds.

High-Quality Materials and Hygiene

- Stainless Steel Construction: Made from high-quality stainless steel, ensuring durability and hygiene.

- Easy Cleaning: Designed for easy disassembly and cleaning, reducing downtime for maintenance.

advanced Automation

- Depositing and Extruding: Equipped with both depositing and extruding capabilities, allowing for the production of center-filled marshmallows and various shapes.

- Touch Screen Control: Features a user-friendly touch screen interface for easy operation and precise control.

Applications

- Confectionery Industry: Ideal for professional candy production enterprises looking to meet market demand for diverse marshmallow products.

- Food Processing: Can be used in the production of composite foods that combine marshmallows with biscuits, ice cream, and more.

Technical Specifications

- Material: Stainless steel for durability and hygiene.

- Production Capacity: Varies by model to suit different production scales.

- Power Supply: Standard electrical requirements for easy installation.

- Control System: PLC with touch screen for easy and precise operation.

Advantages

- High Efficiency: Continuous production ensures high output and consistent quality.

- Cost-Effective: Reduces labor costs and minimizes waste, contributing to lower production costs.

- Customizable: Can be tailored to meet specific production needs and customer demands.

Conclusion

The automatic marshmallow production line is a comprehensive solution for efficient and high-quality marshmallow production. It offers versatile capabilities, advanced automation, and hygienic design, making it an excellent investment for businesses looking to enhance their production efficiency and product quality.

Marshmallow Cooking and Continuous Aeration System

The marshmallow production line is a continuous aeration production equipment that is delivered in full sets, from raw material boiling to drying and packaging. This production technique was very expensive in the past, but now it is more accessible and competitively priced.

Key Components and Features

Raw Materials Cooking System: This system is responsible for cooking and preparing the raw ingredients needed for marshmallow production, such as sugar, water, corn syrup, and gelatin.

Aerated System with Color Dosing Unit: The aerated system introduces air into the marshmallow mixture, creating the characteristic light and fluffy texture. It also includes a color dosing unit for adding colors and flavors.

Central Filling Function: This function allows for the incorporation of fillings, flavors, or other ingredients into the marshmallow mixture, enabling the production of a wide range of flavored or filled marshmallow products.

Inflating System for Marshmallow Production

Inflating System

The inflator is an essential tool in the marshmallow production line. It injects air or carbon dioxide gas into the marshmallow mixture to create a light and fluffy texture. This process also imparts a unique taste and look to the candy floss. The controlled accuracy and speed of our inflator guarantee evenness of softness in every marshmallow produced, thereby meeting market needs consistently.

Equipment Safety and Hygiene

- Safety Standards: The equipment is designed with safety in mind, ensuring quality control during food manufacturing processes.

- Hygiene Standards: High standards of hygiene are maintained to keep the marshmallows safe for consumption.

Applications

- Confectionery Industry: Ideal for professional candy production enterprises looking to meet market demand for diverse marshmallow products.

- Food Processing: Can be used in the production of composite foods that combine marshmallows with biscuits, ice cream, and more.

Technical Specifications

- Material: Stainless steel for durability and hygiene.

- Production Capacity: Varies by model to suit different production scales.

- Power Supply: Standard electrical requirements for easy installation.

- Control System: PLC with touch screen for easy and precise operation.

Conclusion

The automatic marshmallow production line offers versatile capabilities, advanced automation, and hygienic design, making it an excellent investment for businesses looking to enhance their production efficiency and product quality. The inflating system ensures efficient and precise production processes, delivering high-quality and consistent products.

Marshmallow Extruding System

The automatic marshmallow production line offers versatile capabilities, advanced automation, and hygienic design, making it an excellent investment for businesses looking to enhance their production efficiency and product quality. The extruding system ensures efficient and precise production processes, delivering high-quality and consistent products.

Versatile Extrusion Capabilities

- Color Options: The marshmallow candy extrusion machine can produce marshmallows in one or four colors, providing a wide range of visual appeal.

- Center-Filled: Capable of creating marshmallows with fillings such as jam or chocolate, adding variety and enhancing the flavor experience.

- Twisted and Shaped Variations: The machine can produce twisted marshmallows and various other shapes, catering to different consumer preferences and market demands.

#High-Quality Production

- Precision Control: Ensures consistent quality and uniformity in every marshmallow produced.

- Efficient Production: The system is designed for continuous production, ensuring high output and meeting market demands efficiently.

#Safety and Hygiene

- Hygienic Design: Constructed from high-quality stainless steel, ensuring a hygienic and safe production process.

- Easy Cleaning: Designed for easy disassembly and cleaning, reducing downtime for maintenance and ensuring a safe production environment.

#Applications

- Confectionery Industry: Ideal for professional candy production enterprises looking to meet market demand for diverse marshmallow products.

- Food Processing: Can be used in the production of composite foods that combine marshmallows with biscuits, ice cream, and more.

#Technical Specifications

- Material: Stainless steel for durability and hygiene.

- Production Capacity: Varies by model to suit different production scales.

- Power Supply: Standard electrical requirements for easy installation.

- Control System: PLC with touch screen for easy and precise operation.

Marshmallow depositing function

Our marshmallow production line is designed to produce a wide variety of marshmallow candies with different shapes and types. Here are some of the key products it can create:

Traditional Monochrome or Multi color Marshmallows

- Single-Color Marshmallows: Classic marshmallows with a uniform color throughout.

- Multi-Color Marshmallows: Marshmallows featuring multiple colors, either in a mixed pattern or distinct sections, adding visual appeal and variety.

Marshmallows with Fillings

- Jelly-Filled Marshmallows: Marshmallows with a delicious jelly filling in the center, offering a combination of soft marshmallow texture and burst of fruity flavor.

- Chocolate-Filled Marshmallows: Marshmallows filled with rich chocolate, creating a delightful contrast between the smooth marshmallow and creamy chocolate center.

Specially Shaped Marshmallows

- Center-Filling Ball Shapes: Marshmallows shaped like balls with a filling at the center, perfect for a surprise burst of flavor.

- Ice Cream Shapes: Marshmallows designed to resemble ice cream scoops, adding a fun and nostalgic touch to your product line.

- 3D Marshmallows: Marshmallows crafted in three-dimensional shapes, providing a unique and engaging visual experience for consumers.

The production line's versatility allows it to meet diverse market demands and consumer preferences, making it an excellent choice for businesses looking to expand their product offerings and capture a larger share of the confectionery market.

Marshmallow Automatic Drying System

The marshmallow automatic drying system is an essential component in modern marshmallow production. It combines efficient drying technology with hygienic design to ensure high-quality, safe, and consistent products. Whether you're a small bakery or a large-scale producer, this equipment can significantly improve your production capabilities and meet market demands.

Efficient Drying Process

The marshmallow automatic drying system is designed for efficient and hygienic drying of marshmallows after forming. It ensures optimal moisture removal to achieve the desired texture and shelf life.

Automated Operation

- Fully Automatic: Requires no manual intervention until the packing stage, streamlining the production process and reducing labor costs.

- Continuous Drying: The system can operate continuously, ensuring high production efficiency.

Versatile Applications

- Wide Range of Products: Suitable for drying various types of marshmallows, including traditional shapes, twisted ropes, and center-filled varieties.

- Customizable Drying Time: Can be customized for drying times ranging from 3 to 24 hours, depending on product requirements.

Hygienic and Durable Design

- Stainless Steel Construction: Made from high-quality stainless steel, ensuring durability and ease of cleaning.

- Food-Grade Materials: All contact parts are food-grade certified, maximizing food safety.

Advanced Drying Technology

- Vacuum Drying: Utilizes low-pressure environments to remove moisture faster than traditional methods, resulting in light and fluffy marshmallows.

- Infrared Drying: Some systems use infrared technology to apply heat directly to the marshmallows, accelerating the drying process while maintaining optimal moisture levels.

Applications

- Marshmallow Production: Ideal for both small and large-scale production facilities aiming to enhance product quality and production efficiency.

- Gummy candy Processing: Suitable for food processing facilities producing a wide range of confectionery products.

Technical Specifications

- Production Capacity: Varies by model, typically ranging from 50 to 500 kg/h.

- Power Supply: Standard electrical requirements for easy installation.

- Control System: Equipped with advanced PLC and touch screen controls for precise operation.