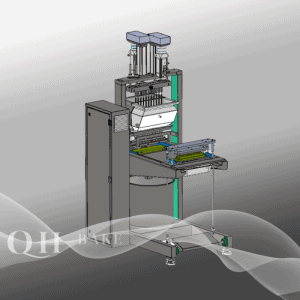

Our Automatic Starchless Depositing Production Line represents a significant leap forward in candy manufacturing technology, offering unparalleled precision, versatility, and efficiency.

Updated in 2015 with state-of-the-art servo depositing technology, this production line uses a screw-type depositor that is not only quieter but also enhances accuracy by 20% compared to traditional chain-type depositors.

Key Features and Benefits

1. Advanced Servo Depositing Technology

- Quieter Operation: The screw-type depositor operates with significantly reduced noise levels, creating a more pleasant working environment.

- Enhanced Accuracy: Improved accuracy by 20% ensures consistent product quality and reduces waste.

2. Versatile Candy Production

- Multiple Styles: The production line can create a wide variety of candy styles, including:

- Center-Filled Candies: Candies with a delicious filling at the center.

- Two-Color Strips: Candies with visually appealing two-color stripes.

- Side-by-Side: Candies with different colors or flavors side by side.

- Layer-by-Layer: Candies with multiple layers of different textures or flavors.

- Multi-Color and Multi-Style Candies: Offering endless possibilities for creative and unique candy designs.

3. Diverse Candy Types

- Hard Candies: Produce classic hard candies with a variety of flavors and colors.

- Lollipops: Create fun and colorful lollipops for all ages.

- Soft Candies: Manufacture soft, chewy candies with a smooth texture.

- Taffies: Make delicious taffies with a perfect balance of softness and chewiness.

- Functional and Sugar-Free Candies: Utilize different cooking systems to produce candies with functional ingredients or sugar-free options, catering to a wide range of consumer preferences.

4. Automated Processes

- Automatic Weighing and Cooking of Raw Materials: Ensure precise measurement and consistent cooking of raw materials.

- Automated Mixing of Raw Materials: Achieve uniform mixing for a consistent product quality.

- Automatic Weighting and Mixing of Flavors, Pigments, Acids, and Functional Additives: Enhance the customization of flavors and functional properties, allowing for the production of unique and innovative candy products.

Why Choose Our Automatic Starchless Depositing Production Line?

- Precision and Consistency: The servo depositing technology ensures that every candy is produced with high precision and consistency.

- Versatility: The ability to produce a wide variety of candy styles and types makes this production line suitable for any manufacturer looking to diversify their product offerings.

- Efficiency: Automated processes reduce labor requirements and increase production efficiency, allowing for higher output with fewer resources.

- Innovation: Stay ahead of the competition with the ability to produce unique and functional candies that meet the evolving demands of the market.

Our Automatic Starchless Depositing Production Line is the perfect solution for manufacturers seeking to enhance their production capabilities, improve product quality, and expand their product range. Experience the future of candy manufacturing with our advanced and versatile production line.

|

QG-80 Capacity:80kg/hSpeed:15,000pcs/hLength:≈26’ |

|

QG-150

Speed:60,000pcs/h Length:≈46’ |

|

QG-300

Speed:120,000pcs/h Length:≈61’ |

|

QG-600

Speed:240,000pcs/h Length:≈94’ |

|

QG-1500 |

Fully Automated Gummy Cooking System

Our industrial-grade gummy cooking equipment has empowered manufacturers to significantly reduce labor dependence and minimize batch variations caused by complex auxiliary devices in traditional processes.

Automatic SmartGel Cooking System

Next-Generation Gummy Manufacturing Solutions

Transform your confectionery production with SmartGel AutoCooking System—the fully automated, precision-engineered solution designed for modern gummy manufacturers seeking unmatched consistency, flexibility, and efficiency.

1. Eliminate Human Error, Boost Consistency

Our AI-driven batch mixing system replaces manual processes with:

- ±0.1% Smart Weighing Accuracy (60% more precise than traditional flow control)

- ±0.5°C Dynamic Temperature Control for sensitive ingredients like probiotics and vitamin C

- <1.5% Batch Variance ensures identical quality across productions

2. Formula Freedom, Future-Proof Design

Adapt seamlessly to any recipe, from classic gels to cutting-edge innovations:

- Multi-gel compatibility: pectin, gelatin, carrageenan, and hybrid blends

- Specialized configurations for:

→ Sugar-free formulations

→ Heat-sensitive additives (e.g., probiotics, vitamins)

→ Challenging ingredients (powders, oils, acidic compounds)

3. Industrial-Grade Reliability

Powered by globally trusted components:

- Siemens PLC & Omron Closed-Loop Control

- Mettler Toledo Weighing Modules

- ABB Servo Drives & Yokogawa Sensors

Key Innovations

AutoBlend Pro Technology

- Magnetic stirring + real-time heating synchronizes ingredient integration

- Optional in-line homogenizer for ultra-uniform texture

Customizable Add-Ons

- Low-temperature dosing chambers (10-15°C)

- CIP cleaning systems

- FDA-compliant batch tracking (21 CFR Part 11)

---

Tangible Results for Your Business

✅ 83% Labor Reduction (0.5 operators per batch)

✅ 40% Faster Formula Changeovers

✅ 30% Less Material Waste

✅ >98% Nutrient Retention in sensitive components

Certified Excellence

ISO 22000 & CE certified. Scalable from pilot lines to full-scale production.

Ready to Revolutionize Your Production?

[Contact Us] for a customized solution analysis – because every gummy deserves perfection.

SmartGel AutoCooking System: Where Precision Meets Possibility.

Key Features Overview

Key Features Overview

| Technology | Capability |

|---|---|

| Smart Batch Mixing | Auto-weighing, heating, stirring sync |

| Multi-Gel Reactors | Pectin/gelatin/carrageenan optimized |

| NutrientGuard™ | Protects heat-sensitive ingredients |

| Pharma-Grade Traceability | Full batch documentation & compliance |

Global Installations | 24/7 Technical Support | 5-Year Performance Warranty

Sugar sanding system

A sugar sanding machine is an automated industrial device used to evenly apply sugar or sugar-based coatings onto food products. It streamlines the process of adding a sweet, decorative, or textural layer to items like candies, baked goods, and confectionery. Here's a detailed breakdown:

Key Components & Functionality

Feeding System

Products enter via a conveyor belt or vibrating feeder, ensuring consistent placement for coating.

Sugar Application Mechanism:

Dry Method: Sprinkles granulated, powdered, or colored sugar using vibrating screens, spray nozzles, or rotating brushes.

Wet/Dry Combination: Applies a syrup or adhesive layer first (e.g., honey or starch glue), followed by sugar for better adhesion.

Drum/Tumbler: Rotates products in a drum to coat them evenly, commonly used for dragées (sugar-coated almonds) or candies.

Excess Sugar Management:

Recycles unused sugar through sieves or vacuums to minimize waste.

May include brushes or air jets to remove excess coating.

Control System:

Adjusts sugar quantity, conveyor speed, and application intensity for customization.

Ensures uniformity and precision in coating thickness.

Q&A

How to wrap sour sand smoothly on gummy candy?

The machine contains three internal layers, filled with sour sand or white sugar. These materials are continuously rotated by the machine's roller structure and fall through a sieve onto the candies being transported inside.The candy keeps rotating along with the drum.

How to ensure that the excess white sugar will not fall out with the candy during the sanding process?

The screw of the sugar layer spirals inward, while the candy spirals outward, allowing for complete reuse without removal.

Oil/wax coating system

A gummy candy oil/wax coating system is a process used in confectionery manufacturing to apply a thin, edible layer of oil, wax, or a blend of both to gummy candies. This system enhances product quality, shelf life, and consumer appeal. Below is a detailed breakdown:

Purpose of Coating

Anti-Sticking: Prevents candies from adhering to each other or packaging.

Glossy Finish: Provides an attractive shine.

Moisture Barrier: Reduces moisture loss or absorption, maintaining texture.

Preservation: Extends shelf life by protecting against environmental factors.

Materials Used

Oils: Food-grade vegetable oils (e.g., coconut, sunflower, palm kernel oil).

Waxes: Natural waxes like carnauba (plant-based) or beeswax; sometimes synthetic options like candelilla

Combinations: Blends of oil and wax for balanced texture and shine (e.g., 90% oil + 10% wax).

Equipment & Process

Coating Application:

Tumbling Drum: Gummies are rotated in a drum while oil/wax is sprayed evenly.

Conveyor Spray System: Candies pass through a misting tunnel on a conveyor belt.

Temperature Control: Waxes are heated to liquid form, then cool to solidify post-application.

Drying/Cooling:Coated candies are air-dried or cooled to set the coating.

Quality Control

Uniformity: Ensures even coating without clumps.

Adhesion: Tests to confirm coating durability during handling.

Sensory Checks: Verifies gloss, texture, and taste (no off-flavors from coatings).

Regulatory Considerations

Food-Grade Compliance: Oils/waxes must meet FDA (U.S.) or EFSA (EU) standards as GRAS (Generally Recognized As Safe).

Labeling: Allergens (e.g., coconut oil) must be declared on packaging.

Challenges

Texture Balance: Avoiding excessive wax that creates a "waxy" mouthfeel.

Temperature Sensitivity: Ensuring waxes solidify correctly without melting during storage.

Cost: Natural waxes (e.g., carnauba) can be expensive.

Examples

Haribo Goldbears: Use a beeswax/carnauba wax blend for shine.

Trolli Gummi Worms: Often coated with coconut oil to prevent sticking.

Environmental & Efficiency Factors

Waste Reduction: Systems optimize spray efficiency to minimize excess.

Energy Use: Heating waxes requires energy-efficient equipment.

Conclusion

The oil/wax coating system is a critical step in gummy production, balancing aesthetics and functionality. Innovations focus on sustainable materials and energy-efficient application methods to meet consumer and regulatory demands.

How do you make the surface of gummy candy shiny?

The surface of candy can exhibit various effects; some may appear crystal clear and shiny, while others may have a layer of acid sand coating them. The shiny surface usually form the last step to coating the eatable wax or oil on the coating drum.

What kind of substance is coated on the surface of the gummies? Is it edible?

Yes,usually by carnauba wax is mixed with a neutral oil like grapeseed or sunflower

How does this machine works?

The formed candies are placed in the coating drum. The machine is equipped with an independent oil spraying system. The soft candies are coated with wax and oil while spirally rotating on the wall of the tube.

Full Automated gummy Candy Drying Line

1. System Architecture Design

1.1 Intelligent Linkage Module

- Flexible conveyor chain integrated with forming equipment (±0.5mm visual positioning)

- Multi-stage buffer system (≥30min production continuity during downtime)

1.2 3D Drying System

- Modular tunnel structure (6m/base unit, expandable to 12 units)

- Tri-dimensional hot air circulation (±1.5℃ uniformity)

- Multi-layer vertical drying (300% space utilization improvement)

1.3 Dynamic Dehumidification Unit

- Dual-stage rotary dehumidifier (-40℃ dew point)

- Real-time humidity feedback (±2%RH control)

- Waste heat recovery (≥35% energy efficiency)

2. Core Technical Specifications

- Capacity: 200-2000kg/h (modular scalability)

- Energy Consumption: 0.18kW·h/kg (42% reduction vs conventional)

- Moisture Control: ±0.3% variance

- Hygiene Compliance: FDA 21 CFR Part 117 certified

3. Value-Added Services

3.1 Process Optimization Lab

- Formula-drying curve matching

- Material database (87 gum base variants)

3.2 Digital Twin Platform

- 5G-enabled remote monitoring

- Batch traceability (10-year data retention)

3.3 Sustainability Solutions

- Waste-heat power generation (optional)

- Photovoltaic integration (carbon-neutral certified)

4. Implementation Roadmap

4.1 Analysis Phase (3-5 days)

- 3D site scanning & modeling

- Production rhythm simulation

4.2 Integration Phase (8-12 weeks)

- Modular pre-assembly testing

- Synchronized control commissioning

4.3 Delivery Phase (1 week)

- AR-assisted operation training

- Predictive maintenance deployment

5. Economic Benefits Model

(For 5,000t annual production):

- 76% labor cost reduction (5-15 positions eliminated)

- 100% tray investment saved (2,000-10,000 trays eliminated)

- $40k/year energy savings (@$0.12/kWh)

- 0.7% quality loss reduction

This turnkey solution enables10- 18month ROI through electromechanical integration and full lifecycle services. Special configurations available for 3D-shaped candies (vacuum adsorption conveying). All systems comply with FSMA modernization requirements.

---

This version maintains technical precision while optimizing for international industry terminology and presentation standards. Would you like to adjust any specific technical parameters or emphasize particular features?