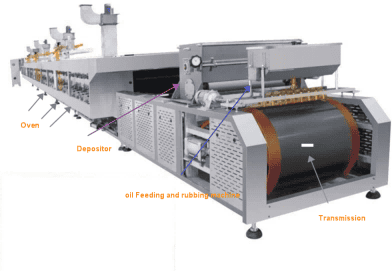

The Layer Cake/Swiss Roll Production Line is an excellent investment for businesses in the bakery and food processing industries. With its advanced features, versatile applications, and hygienic design, it ensures efficient production and consistent product quality. Whether you're producing layer cakes, Swiss rolls, or other sliced cakes, this equipment provides precise control over the production process, making it an ideal choice for enhancing your production capabilities and meeting market demands.

Features and Advantages

1. No Mold Required: This production line allows for cake production without the need for molds. By simply changing the cutting blade gap and adjusting the speed of the horizontal cutting knife, the size of the cake can be easily customized.

2. High Automation: The entire production process is automated, from mixing and depositing to baking, cooling, cutting, and packaging, reducing manual intervention and increasing production efficiency.

3. Versatile Applications: Suitable for producing a wide range of products, including layer cakes, Swiss rolls, and various types of sliced cakes.

4. Energy Efficiency: The line can be equipped with either electric or gas heating options, adapting to different energy sources and helping customers control production costs.

5. Hygienic Design: Constructed from high-quality stainless steel, ensuring food safety and ease of cleaning.

6. Digital Control: Equipped with a PLC control system and touch screen interface for easy operation and precise control over production parameters.

7. Space-Saving: Despite its 8m length, the compact design saves space and is easy to integrate into existing production lines.

Working Process

1. Raw Material Mixing and Aerating: The process begins with the mixing and aerating of raw materials such as flour, sugar, eggs, and oil to create a smooth batter.

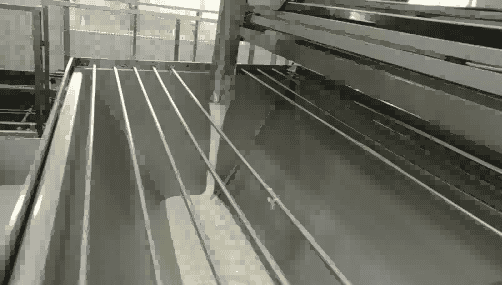

2. Depositing onto Steel Belt: The batter is deposited onto a steel belt, which transports it into the oven for baking.

3. Oven Baking: The batter is baked in a steel belt tunnel oven, ensuring even cooking.

4. Ring Reverse Cooling: After baking, the cake is cooled using a ring reverse cooling system to stabilize its structure.

5. Vertical Cutting: The cooled cake is then vertically cut into strips.

6. Cream Spreading and Filling: Cream or other fillings are spread onto the cake strips.

7. Rolling/Folding System: The filled cake strips are rolled or folded into the desired shape.

8. Horizontal Cutting: The rolled or folded cake is horizontally cut into individual pieces.

9. Material Arrangement and Packaging: The final products are arranged and packaged for distribution.

Applications

- Layer Cakes: Ideal for producing various types of layer cakes.

- Swiss Rolls: Perfect for creating Swiss rolls with different fillings and flavors.

- Slice Cakes: Suitable for producing a wide range of sliced cakes, including mini Swiss rolls and other similar products.

Technical Specifications

- Material: Stainless steel for durability and hygiene.

- Production Capacity: Varies by model to suit different production scales.

- Power Supply: Standard electrical requirements for easy installation.

- Control System: Equipped with advanced PLC and touch screen controls for precise operation.

| Production Capacity | Oven Length M |

Gas oven KG/H |

Electirc oven

KW |

Total length M |

| 300 | 16 | 20 | 85 | 40 |

| 500 | 39 | 35 | 140 | 40-55 |

| 800 | 39 | 50 | 220 | 55-70 |

| 1000 | 39 | 55 | 240 | 55-70 |

es to meet diverse market demands. Here are some of the key products it can create:

ped cakes, our equipment provides a reliable and efficient solution.

Fully Automatic Cake Aerator: Enhancing Efficiency and Quality in Cake Production

Product Features

- Versatile Applications: Suitable for various cake products such as chiffon cakes, sponge cakes, custard pies, mold cakes, meat floss cakes, Swiss rolls, cup cakes, and more. Also applicable for cotton candy, chocolate, ice cream, and other products.

- Efficient Aeration: Utilizes integrated high-speed automatic aeration technology to overcome the rough texture, instability, short shelf life, and poor taste of traditional egg beater products. Results in a finer, more stable product with better color, taste, and longer shelf life.

- High Automation: The system consists of pre-mixing, aeration, conveying, cooling, and control systems, enabling full automation from mixing to high-speed aeration, saving labor and time.

- Precision Control: With a PLC control system, it can store and manage hundreds of different product parameters and formulas, ensuring consistent and stable product quality.

- Flexible Adjustment: Can be adjusted for separate egg white or whole egg aeration based on user needs, meeting diverse production requirements.

- Easy to Clean: Designed for easy cleaning to reduce material waste and improve production efficiency.

Working Principle

1. Pre-mixing: All raw materials are pre-weighed and placed into the pre-mixing tank, added in the order and quantity specified by the formula.

2. Aeration: After the pre-mixing program is completed, the material is transferred to the aeration mixing head for aeration.

3. Material Conveying: The aerated material is conveyed from the mixing head to the outlet pipeline for subsequent processes such as filling and shaping.

Applications

- Cakes: Chiffon cakes, sponge cakes, custard pies, mold cakes, meat floss cakes, Swiss rolls, cup cakes, etc.

- Candies: Cotton candy, aerated candies, etc.

- Other Foods: Chocolate, ice cream, etc.

Operation Process

1. Preparation: Turn on the power and check all components.

2. Pre-mixing: Add ingredients to the pre-mixer and start.

3. Aeration: Transfer pre-mixed material to the aeration system.

4. Conveying and Shaping: Convey aerated material to subsequent equipment for shaping and packaging.

Advantages

- High Efficiency: Reduces manual intervention, saving time and labor costs.

- Quality Improvement: Ensures fine texture, stability, good color, excellent taste, and longer shelf life.

- Flexibility: Adaptable to various production needs.

- Easy Maintenance: Easy to clean, reducing waste and improving efficiency.

Conclusion

The fully automatic cake aerator is essential for modern cake production, offering efficient and high-quality solutions. It meets the needs of both small bakeries and large food factories, helping businesses stand out in the competitive market.

Cake Steel Belt Oven: Efficient and Versatile Baking Solution

Efficient Baking

The cake steel belt oven is designed for continuous baking of cakes and other baked goods. It uses a steel belt as the conveyor system, ensuring even heat distribution and consistent baking results.

The cake baking tunnel oven offers a versatile and efficient solution for cake production, with options for natural gas, electricity, or diesel as energy sources. It enhances production efficiency, ensures consistent product quality, and is an excellent investment for businesses in the bakery and food processing industries. Whether you're a small bakery or a large-scale producer, this equipment can significantly improve your production capabilities and product appeal.

Energy Options

- Natural Gas: Gas-fired tunnel ovens are commonly used for baking a wide range of food products. They offer efficient energy use and can be fueled by natural gas or propane. The gas burners create flames that radiate energy in the oven chamber, heating the contents inside. This type of oven is known for its high-volume baking capacity and consistent results.

- Electricity: Electric tunnel ovens are based on a mature and time-tested system with a proven record of reliable round-the-clock production. They are known for their energy efficiency and flexibility. The ovens are suitable for a variety of products, ranging from buns to bread, cakes, mooncakes, and pastries.

- Diesel: Diesel-fired tunnel ovens provide an alternative energy source, especially useful in regions where gas or electricity may be less accessible or more expensive. They offer similar functionality to gas ovens but with the added benefit of being able to operate independently of gas pipelines.

Precise Temperature Control

- Equipped with advanced temperature control systems to ensure consistent baking, maintaining the quality and texture of the cakes.

- Each temperature zone can be separately regulated for top and bottom heat, allowing for optimal baking conditions for different products.

Space-Saving and Efficient

- The modular design allows for easy and quick assembly, making it adaptable to various production space requirements.

- High insulation ensures that very limited heat escapes from the ovens, resulting in energy savings and a cooler exterior.

Applications

- Cakes: Suitable for baking various types of cakes, including chiffon cakes, sponge cakes, egg yolk cakes, mooncakes, and more.

- Biscuits and Cookies: Can be used for baking hard biscuits, crisp biscuits, fermented biscuits, soda biscuits, and bread.

- Pastries and Pies: Ideal for baking pastries, pies, and other similar products.

The cake steel belt oven offers a reliable and efficient solution for cake production. With its advanced features, versatile applications, and hygienic design, it ensures efficient production and consistent product quality. Whether you're a small bakery or a large-scale producer, this equipment can significantly improve your production capabilities and meet market demands.

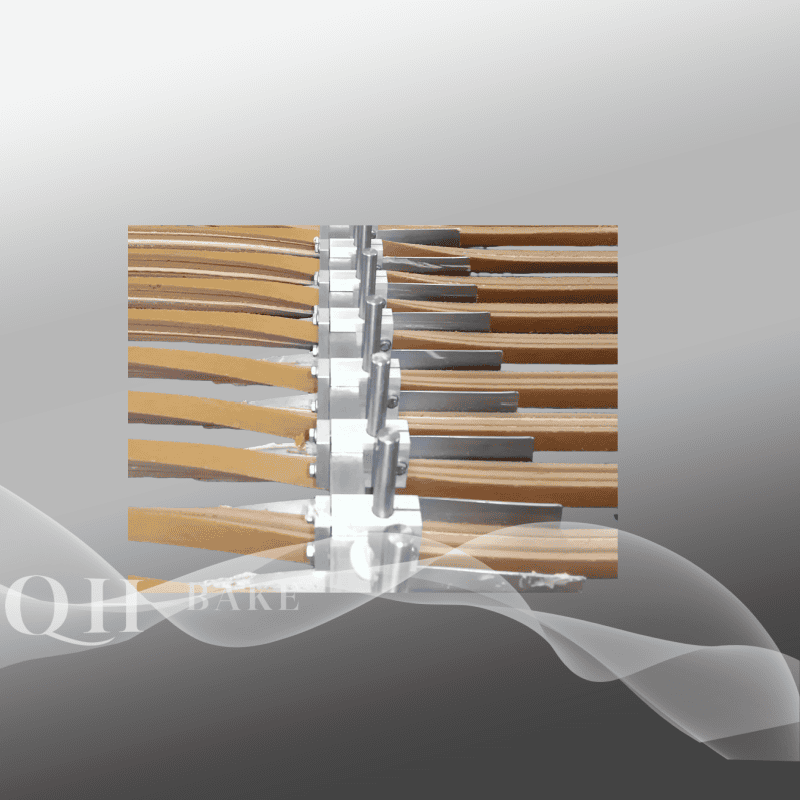

Fully Automatic Layer Cake Cutting Machine

The fully automatic layer cake cutting machine offers a reliable and efficient solution for cake production. With its advanced features, versatile applications, and hygienic design, it ensures efficient production and consistent product quality. Whether you're a small bakery or a large-scale producer, this equipment can significantly improve your production capabilities and meet market demands.

High-Precision Cutting

- Ultrasonic Vibration Technology: Utilizes ultrasonic vibration to cut, ensuring smooth cutting surfaces without compression or heat generation, which maintains the original flavor and taste of the food.

- PLC Control System: Equipped with a PLC control system and touch screen interface for easy operation and precise control over cutting parameters.

- Digital Display: Provides real-time monitoring of production status and parameters, ensuring consistent cutting quality.

Versatile Applications

- Wide Range of Products: Suitable for cutting various types of cakes, including cream cakes, chiffon cakes, sponge cakes, and more.

- Diverse Cutting Shapes: Can cut into various shapes such as slices, rectangles, triangles, and more.

Efficient and Reliable Operation

- High-Speed Cutting: Achieves fast cutting speeds, enhancing production efficiency.

- Low Maintenance: No moving parts, reducing wear and tear and minimizing maintenance requirements.

Hygienic and Durable Design

- Stainless Steel Construction: Made from high-quality stainless steel, ensuring durability and ease of cleaning.

- Food-Grade Materials: All contact materials are food-grade certified, maximizing food safety.

Applications

- Bakery Industry: Ideal for bakeries and cake production facilities aiming to enhance product quality and production efficiency.

- Food Processing: Suitable for food processing facilities producing a wide range of baked goods and confectionery products.

Technical Specifications

- Material: Stainless steel for durability and hygiene.

- Production Capacity: Varies by model to suit different production scales.

- Power Supply: Standard electrical requirements for easy installation.

- Control System: Equipped with advanced PLC and touch screen controls for precise operation.

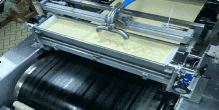

Cake Production Line Rolling Machine

The cake production line rolling machine is an excellent investment for businesses in the bakery and food processing industries. With its advanced features, versatile applications, and hygienic design, it ensures efficient production and consistent product quality. Whether you're producing layer cakes, Swiss rolls, or other sliced cakes, this equipment provides precise control over the production process, making it an ideal choice for enhancing your production capabilities and meeting market demands.

Key Components and Functions

- Rolling Mechanism: The rolling machine is equipped with advanced rolling mechanisms to ensure smooth and even rolling of cakes. This helps in achieving the desired thickness and texture for various types of cakes.

- Automatic Feeding and Discharge: The system includes automatic feeding and discharge functions, reducing manual intervention and increasing production efficiency.

- PLC Control System: Equipped with a PLC control system and touch screen interface for easy operation and precise control over production parameters.

- Digital Display: Provides real-time monitoring of production status and parameters, ensuring consistent rolling quality.

Working Principle

1. Depositing onto Steel Belt: The cake batter is deposited onto a steel belt, which transports it into the oven for baking.

2. Oven Baking: The batter is baked in a steel belt tunnel oven, ensuring even cooking.

3. Rolling Mechanism: After baking, the cake is passed through the rolling mechanism where it is shaped and rolled.

4. Cooling and Cutting: The rolled cake is cooled and then cut into desired shapes and sizes.

Applications

- Layer Cakes: Ideal for producing various types of layer cakes.

- Swiss Rolls: Perfect for creating Swiss rolls with different fillings and flavors.

- Slice Cakes: Suitable for producing a wide range of sliced cakes, including mini Swiss rolls and other similar products.

Cake UV Cooling and Sterilization Line

The cake UV cooling and sterilization line is an essential component in modern cake production. It combines efficient cooling and UV sterilization to ensure high-quality, safe, and hygienic products. Whether you're a small bakery or a large-scale producer, this equipment can significantly improve your production capabilities and meet market demands.

The cake UV cooling and sterilization line is designed to efficiently cool and sterilize cakes after baking. It uses a combination of cooling and UV sterilization to ensure high-quality and hygienic products.

Key Components

- Cooling Section: Utilizes cold air or water to rapidly cool the cakes, maintaining their shape and texture.

- UV Sterilization Section: Equipped with UV lamps to kill bacteria and other microorganisms, ensuring food safety and extending shelf life.

Hygienic Design

- Stainless Steel Construction: Made from high-quality stainless steel, ensuring durability and ease of cleaning.

- Food-Grade Materials: All contact parts are food-grade certified, maximizing food safety.

Applications

- Cake Production: Ideal for cooling and sterilizing various types of cakes, including layer cakes, Swiss rolls, and more.

- Food Processing: Suitable for food processing facilities producing a wide range of baked goods and confectionery products.