Last Updated on 06/10/2024 by QHBAKE

Hello, gummy gurus and candy craftsmen! If you’re in the business of churning out chewy confections, you know that a commercial gummy making machine is more than just a piece of equipment—it’s your trusty sidekick in the candy-making adventure.

But what happens when your sidekick needs a little help?

That’s where customer support comes in. In this article, we’ll explore the various forms of customer support available for commercial gummy making machines, ensuring your operation runs as smoothly as a well-lubricated gummy conveyor belt.

And to lighten the mood, here’s a joke for you: Why did the gummy bear go to the dentist? Because it had a sweet tooth!

The Lifeline: Manufacturer’s Support

The first line of defense (or support) for your gummy making machine is typically the manufacturer. Reputable manufacturers offer a range of support services, including:

- Technical Support: A team of experts ready to assist with any operational or technical issues that may arise.

- Training and Demonstrations: Ensuring you and your staff are well-versed in the operation and maintenance of the machine.

- Warranty Services: Coverage for any defects or issues that may occur during the warranty period.

The Knowledge Base: Online Resources

In the digital age, many manufacturers provide a wealth of online resources to assist customers. These can include:

- User Manuals: Detailed guides on operating and maintaining the machine.

- Troubleshooting Guides: Step-by-step solutions for common issues.

- FAQs: Answers to frequently asked questions.

- Video Tutorials: Visual demonstrations of various processes and procedures.

The Human Touch: Personal Customer Service

While digital resources are invaluable, sometimes you just need to speak to a real person. Good customer support services should include:

- Phone Support: A hotline for immediate assistance.

- Email Correspondence: A point of contact for written inquiries.

- On-Site Visits: In some cases, a technician may visit your facility to address more complex issues.

The Preventive Care: Maintenance Programs

A proactive approach to machine care can prevent many issues before they arise. Many manufacturers offer maintenance programs that include:

- Scheduled Check-Ups: Regular inspections to ensure the machine is in optimal condition.

- Preventive Repairs: Addressing potential issues before they become problems.

- Parts Replacement: Timely replacement of wear-and-tear components.

Statistical Data

According to a survey by the North American Gummy Candy Market, customer satisfaction is directly linked to the quality of after-sales service, with 85% of customers citing good customer support as a key factor in their satisfaction.

The Extra Mile: Customized Solutions

For businesses with unique needs or those looking to innovate, some manufacturers offer customized solutions, including:

- Machine Modifications: Tailoring the machine to better suit specific production needs.

- Recipe Development: Assisting in the creation of new gummy recipes using the equipment.

- Scale-Up Support: Helping businesses transition from small-scale to large-scale production.

The Global Network: International Support

In our interconnected world, many manufacturers have established international networks to provide support across different regions, ensuring that no matter where you are, help is never far away.

-

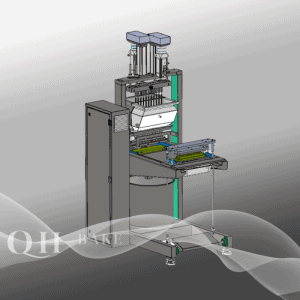

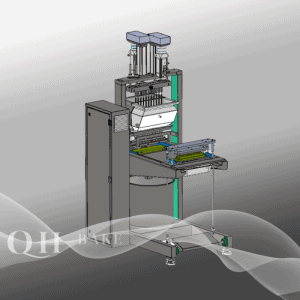

150 Auto starch less gummy candy depositing line: 60,000 gummies/h 280pcs of mold inside machine 8-10PH Cooling unit

-

20S Servo-Form candy depositing Equipment: Cavity PCS: ±20; 100x80x160 Size(cm)

-

300 Auto starch less gummy candy depositing line 120,000 gummies/h 8-10PH Cooling unit 280pcs of twin-mold inside machine

-

50S Servo Control Candy Depositor: Servo; Cavity PCS: ±20; 200x100x170 Size(cm)

Conclusion

When it comes to commercial gummy making machines, having reliable customer support is as essential as the sugar in your gummy recipe. From the manufacturer’s direct support to online resources and personalized customer service, a comprehensive support system ensures that your gummy production runs smoothly, with any issues quickly resolved. So, the next time your gummy machine needs a helping hand, remember that a strong customer support network is your best bet for a sweet success.

Call to Action

Are you looking for a gummy making machine with top-notch customer support? Keep exploring the world of commercial gummy production with us. Stay tuned for more insights and expert advice on selecting the right machinery and support for your business.

-

150 Auto starch less gummy candy depositing line: 60,000 gummies/h 280pcs of mold inside machine 8-10PH Cooling unit

-

20S Servo-Form candy depositing Equipment: Cavity PCS: ±20; 100x80x160 Size(cm)

-

300 Auto starch less gummy candy depositing line 120,000 gummies/h 8-10PH Cooling unit 280pcs of twin-mold inside machine

-

50S Servo Control Candy Depositor: Servo; Cavity PCS: ±20; 200x100x170 Size(cm)

-

600 Auto starch less gummy candy depositing line: 240,000 gummies/h 10-20 PH Cooling unit 520pcs of twin-mold inside machine

-

80 Automatic Gummy Candy Production Line: 40,000 gummies/h 5-8PH Cooling unit 200pcs of mold inside machine

-

Automatic Konjac Pearl Making Machine For Sales – Supplier & Manufacuture

-

Automatic Lollipop Production Line For Sale – Candy Machine Factory

-

Automatic Starch-less Depositing Production Line: Revolutionizing Candy Manufacturing