The QHBAKE pancake machines, with models QH500, QH1000, and QH1600, are state-of-the-art automatic dorayaki cake making machines. These machines are designed to meet the high-volume production needs of the food industry while ensuring product quality and consistency.

| Model |

QH500 |

QH1000 |

QH1600 |

| Production capacity(pieces/h) |

2000 |

5000 |

8000 |

| Total length |

24m |

28m |

32m |

| Electric power |

140kw |

180kw |

240kw |

| Gas Consumption(kg/h) |

35 |

40 |

55 |

The production capacity of the QHBAKE pancake machines varies depending on the model. The QH500 can produce 2000 pieces per hour, the QH1000 can reach 5000 pieces per hour, and the QH1600 has an impressive production capacity of 8000 pieces per hour. This wide range of production capabilities makes it suitable for businesses of different scales, from medium-sized bakeries to large-scale food production factories.

- Total Length: The machines also differ in length. The QH500 has a total length of 24m, the QH1000 is 28m long, and the QH1600 extends to 32m. This length is carefully designed to accommodate all the necessary production processes within the machine's structure.

- Electric Power: In terms of power consumption, the QH500 requires 140kw, the QH1000 needs 180kw, and the QH1600 consumes 240kw. These power requirements ensure that all components of the machine, such as the heating elements, motors, and mixers, operate efficiently.

- Gas Consumption: For models that use gas, the gas-consumption rates are 35kg/h for QH500, 40kg/h for QH1000, and 55kg/h for QH1600. The gas-powered systems are optimized for efficient heat generation, contributing to the overall baking process.

The first step in the production process is the accurate measurement of ingredients. Ingredients such as sugar, flour, glucose, eggs, chocolate, milk powder, flavor, and color are precisely weighed according to a carefully developed formula. This ensures the consistent taste and quality of the final product.

These measured ingredients are then poured into a high-speed mixer. The mixer's powerful blades work to thoroughly blend the ingredients, creating a smooth and uniform batter. This batter consistency is crucial as it affects the texture and appearance of the dorayaki cakes.

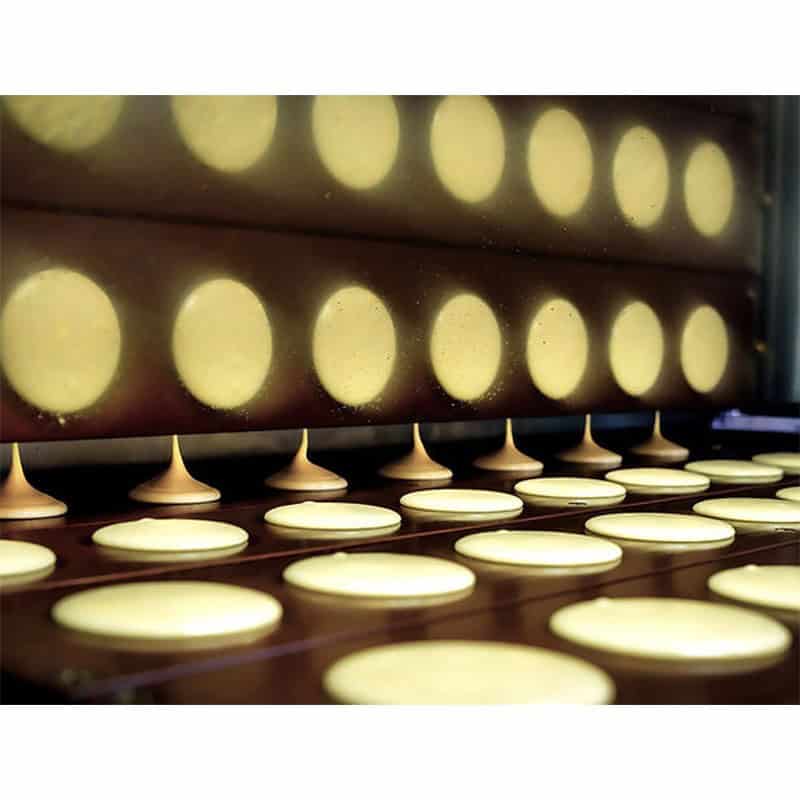

Once the batter is ready, it is poured into a pouring hopper. The hopper is designed to distribute the batter evenly onto each baking sheet. Before pouring, the baking pan is preheated. This preheating step is essential as it allows the batter to expand evenly during the baking process, resulting in a well-formed and consistent-sized cake. After pouring, the baking process can begin.

The baking process is a critical stage in the production of dorayaki cakes. Multiple fire-exhaust pipes are installed in the baking chamber to ensure even heat distribution. This design feature is key to making sure that each cake is heated consistently, preventing local burning or undercooking.

Some gas-oven models are also equipped with an upper heating device. This upper heating element works in tandem with the fire-exhaust pipes, heating the cakes from both the top and the bottom. This dual-heating approach further enhances the baking effect, resulting in a golden-brown, evenly-cooked cake with a delicious texture.

The baking trays used in the QHBAKE pancake machines are made of copper plates. Copper is chosen for its excellent thermal conductivity. This property allows the baking tray to quickly transfer heat to the dorayaki cakes, enabling them to cook in a short time. Additionally, the smooth surface of the copper plate makes it easy to clean, preventing batter from sticking and ensuring hygienic production conditions.

The feed-transfer belt plays a vital role in this stage. It smoothly conveys the unbaked dorayaki baking tray to the turning and baking area of the machine.

The turning device is the core component of this process. It consists of a high-precision mechanical arm and specially designed clamping components. These components work together to accurately clamp the dorayaki cake and perform a 180-degree turn. This turning motion ensures that both sides of the cake are evenly baked.

The baking chamber in this stage is equipped with two evenly distributed heating tubes. These heating tubes provide a stable and suitable baking temperature for the turned-over cakes. After the cakes are turned, the feeding-transfer belt continues to move them through the baking chamber, ensuring that the baking process is completed evenly on both sides.

- Rack and Wall Panels: The machine's structure starts with a rack made of square-pipe welding, providing a sturdy framework. The wall panels are made of 3mm stainless steel, which not only ensures durability but also meets food-grade hygiene standards.

- Conveyor Belt: A 6mm strip Pu conveyor belt is used to transport the cakes through this stage. This type of conveyor belt is chosen for its flexibility, durability, and ability to handle the movement of the cakes without causing damage.

- Interception and Arrangement Device: The front section of the machine is equipped with a roller-type interception and arrangement device. This device helps to organize the cakes in a proper order, making it easier for subsequent processes.

- Filling and Finishing Devices

- A needle-cylinder type core injection machine is used for precise filling. This machine ensures that the filling, such as sweet bean paste or other flavors, is evenly injected into the cakes.

- Cylinder interception and finishing mechanisms are also in place to further process the cakes, ensuring that the filling is properly distributed and the cakes are in the right shape.

- Printing and Edge-Pressing Devices

- An automatic temperature-controlled printing device is available for adding decorative patterns or brand logos on the cakes.

- A whole row of vacuum-closed cake devices helps to maintain the freshness and shape of the cakes. Additionally, an independent edge-pressing device is installed to seal the edges of the sandwiched cakes, ensuring that the filling does not leak out.

- Rack and Conveyor Belt: The cooling stage begins with a stainless-steel rack, which provides a stable structure for the cooling process. A conveyor belt made of PE material is used to transport the cakes through the cooling area. The PE conveyor belt is chosen for its non-toxic and heat-resistant properties.

- Drive Drum and Motor: The drive drum is a rubber drum, which provides a smooth and stable movement for the conveyor belt. A motor turbine worm reducer is used to power the conveyor belt. This type of reducer offers precise speed control, ensuring that the cakes are cooled at an appropriate rate.

- Sterilization Function: The cooling system is also equipped with an ultraviolet sterilization function. This function helps to eliminate any harmful bacteria or microorganisms on the surface of the cakes, ensuring the safety and hygiene of the final product.

- Transfer to the Next Stage: A small drum is used to quickly transport the cooled cakes to the corner machine, which is usually the next step in the packaging or further processing of the dorayaki cakes.

- To operate the QHBAKE pancake machine efficiently, a workshop space of more than 200 square meters is required. This space is needed to accommodate the machine itself, as well as the movement of workers and the storage of raw materials and semi-finished products.

- The final-product workshop should have an area of more than 100 square meters to store and handle the finished dorayaki cakes. The raw-material workshop also requires more than 100 square meters to store all the necessary ingredients in a proper and organized manner.

Each shift of operation requires 10-15 workers. These workers are responsible for tasks such as monitoring the production process, adding raw materials, handling any machine malfunctions, and ensuring the overall quality of the products.

The QHBAKE pancake machines and the dorayaki cakes produced by them can be seen in the following photos. [Here, if possible, insert the actual photos with proper captions. If the image paths in the original document are valid, use them to display the photos. If not, just mention that photos are available to show the machine's appearance and the final product's look.]

In conclusion, the QHBAKE pancake machines offer a comprehensive and efficient solution for the production of dorayaki cakes. With their high-tech features, precise production processes, and relatively low-maintenance requirements, they are an ideal choice for the food production industry.