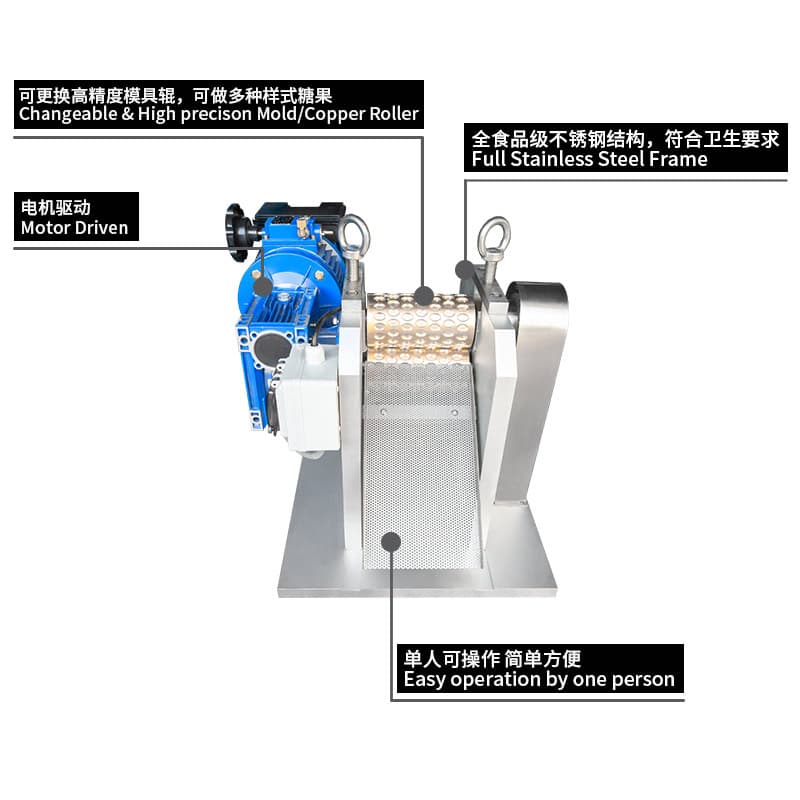

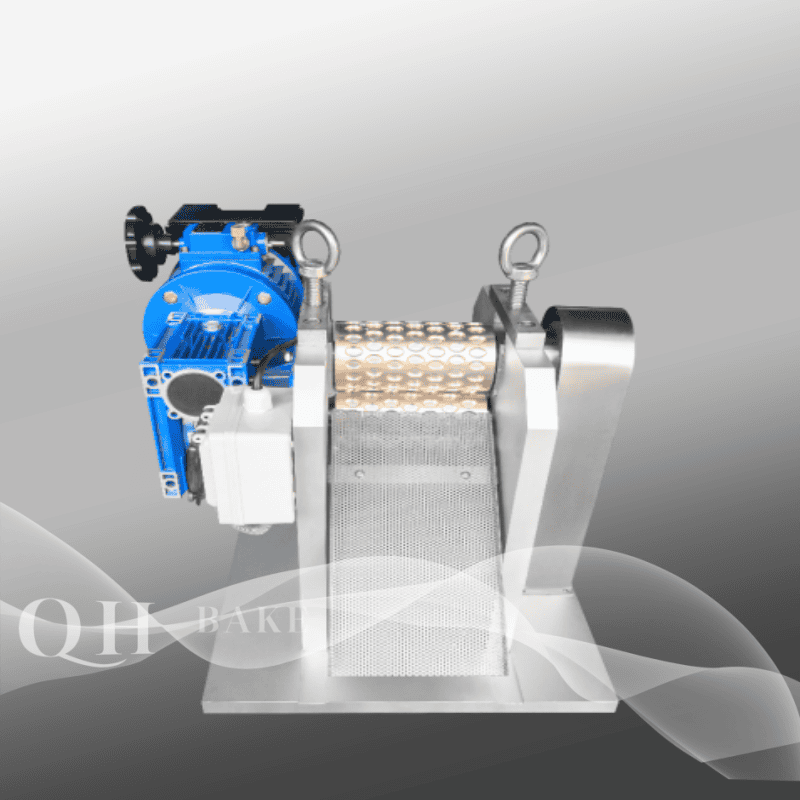

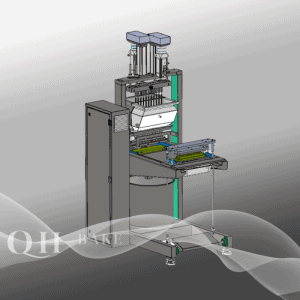

The QHLB100 Candy Drop Roller is designed for low to medium-volume candy production, offering precision, quality, and efficiency in every batch. This machine provides a cost-effective solution for producing die-formed hard candies, eliminating the need for large-scale machinery investment while ensuring high-quality candy output.

Specifications

- Roller Size: 730mm (L) x 520mm (W) x 440mm (H)

- Customization: Available for different capacity and size requirements

- Weight: 64kg

- Power: 1kW

- Materials: Cast steel with food-grade steel contact parts

- Product Types: Hard candy, soft candy, toffee

The QHLB100 Candy Drop Roller is the perfect choice for manufacturers aiming to enhance production efficiency, product quality, and operational convenience.

How It Works

1. Cook and cool your candy ingredients to form a solid block.

2. Feed the candy block into the QHLB100 Candy Drop Roller.

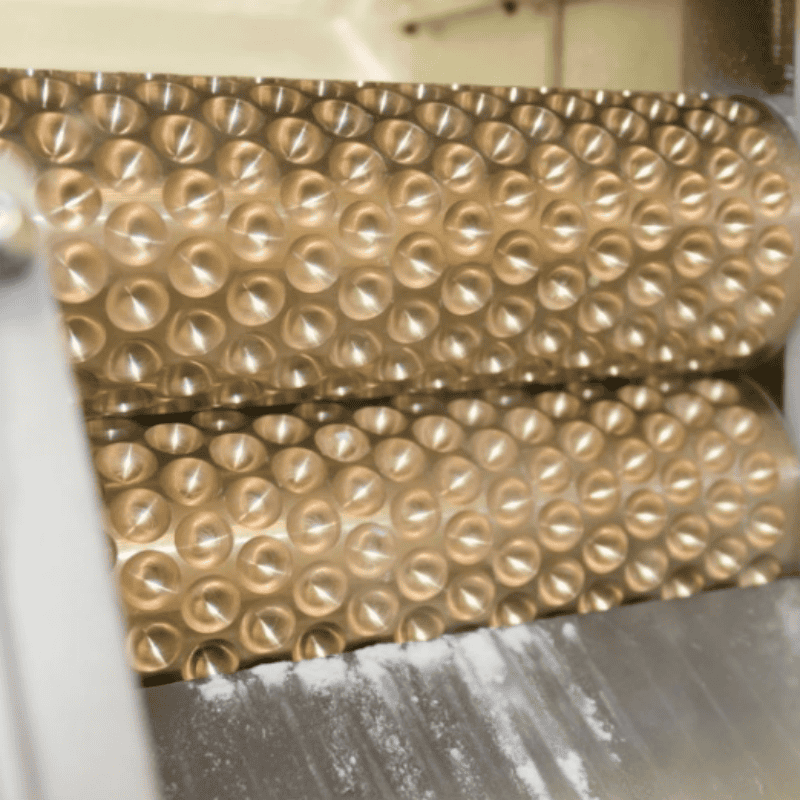

3. The machine's dual rollers will shape the candy into the desired form.

4. Allow the shaped candy to cool.

5. Break the cooled candy block into individual pieces.

6. Sieve the candies to remove any sharp edges or burrs.

7. Package your finished candies.

High Precision:

The rollers are manufactured using a high-precision CNC center, with the distance between the upper and lower rollers maintained at less than 0.5mm (precision of 10um). This ensures beautifully formed products that release easily from the molds.

Space-Saving Design:

The QHLB100 can be placed on tables of any size, making it adaptable to various workspace constraints.

Single-Operator Capability:

Our user-friendly design allows the equipment to be operated by one person, reducing labor costs and increasing operational flexibility. This makes it ideal for small-scale production and R&D environments.

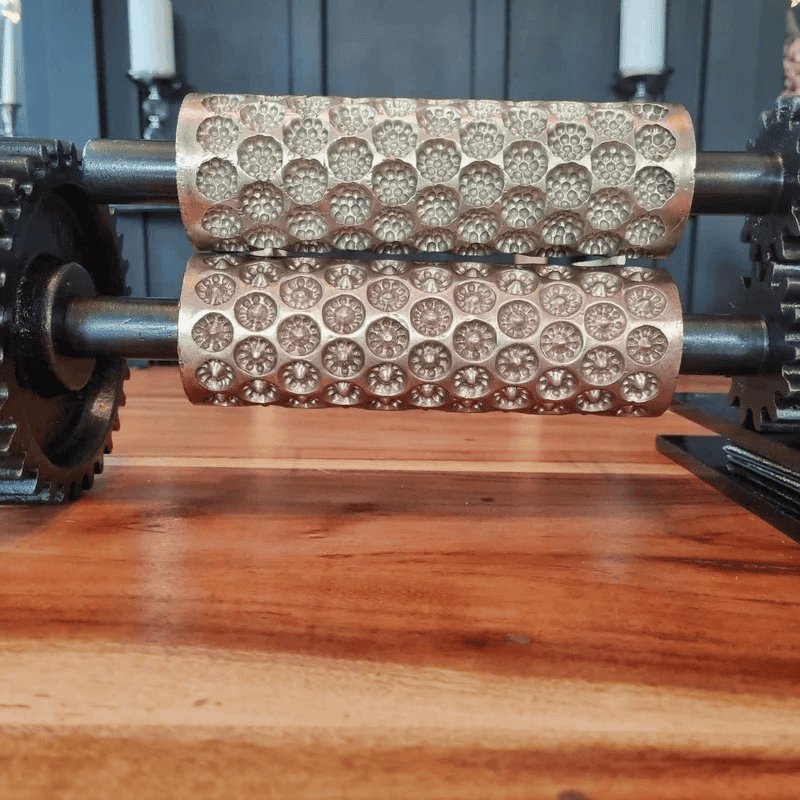

Interchangeable Brass Forming Rollers:

The QHLB100 features interchangeable brass forming rollers that can be quickly and easily replaced without tools. This allows for efficient production of various candy shapes using a single machine, making it perfect for businesses looking to diversify their candy offerings.

Product Shape Options:

The rollers can be engraved with multiple shapes, including ovals, rounds, balls, oblongs, pears, lemons, flat drops, and novelty shapes. Customization options are available to meet specific market demands or creative visions.

Bar Products and Automation Capability:

In addition to traditional candy shapes, the machine can produce bar products using specially designed rollers. The production line can be further automated with additional machinery to enhance efficiency and output.

Production Capacity:

An experienced operator can produce up to 1000kg of formed candies in an 8-hour shift, depending on candy size.