Last Updated on 06/10/2024 by QHBAKE

Hello, baking enthusiasts and cookie connoisseurs! Are you ready to embark on a scrumptious journey through the art of biscuit making? Whether you’re a seasoned baker looking to refine your craft or a novice just starting to dip your toes into the dough, this article is your guide to mastering the biscuit making process.

But first, let’s lighten the dough with a little humor: Why did the biscuit go to the doctor? Because it had a little crumble!

The Art of Biscuit Making

The process of making biscuits is a delicate dance of ingredients, technique, and timing. It’s an art form that transforms a simple mixture of flour, fat, and liquid into a golden, buttery delight. Let’s break down the steps to create biscuits that are as light as a feather and as crisp as the morning air.

Gathering Your Ingredients

The first step in any culinary adventure is gathering your ingredients. For biscuits, you’ll need:

- Flour: The base of your biscuit, often all-purpose or cake flour for a tender crumb.

- Fat: Typically butter or shortening, which creates the flaky layers.

- Leavening Agent: Baking powder or baking soda to give your biscuits height.

- Liquid: Usually milk or buttermilk, which adds moisture and flavor.

- Seasonings: Salt, pepper, and any herbs or spices that suit your taste.

Mixing the Dough

Now that your ingredients are assembled, it’s time to mix. The key to light and flaky biscuits is in the mixing method. Overmixing can lead to tough biscuits, while undermixing can result in uneven distribution of fats and a less desirable texture.

- Combine Dry Ingredients: Start by whisking together your flour, leavening agent, and any seasonings.

- Cut in the Fat: Using a pastry cutter, two knives, or your fingers, cut the cold fat into the dry ingredients until it resembles coarse crumbs.

- Add Liquid: Gradually add your liquid to the mixture, stirring gently until just combined. The dough should be slightly sticky but not overly wet.

Kneading and Shaping

While kneading is generally not recommended for biscuit dough to avoid toughness, gently folding the dough over on itself a few times can help incorporate any dry ingredients and create a more uniform texture.

Once your dough is ready, it’s time to shape your biscuits. You can use a biscuit cutter, a glass, or even the edge of a spoon to cut out rounds of dough, placing them onto a baking sheet.

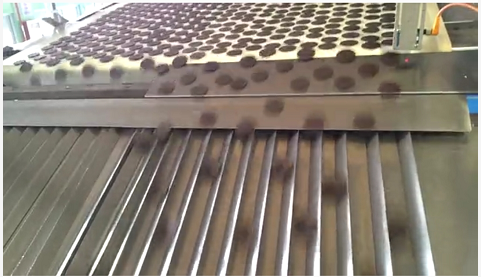

Baking the Biscuits

Preheat your oven to a hot 425°F (220°C) and bake your biscuits for 10-15 minutes, or until they’re golden brown and cooked through. The high temperature is crucial for creating a crispy exterior while keeping the inside tender.

Statistical Data

According to the International Biscuit Manufacturers Association, the global biscuit market was valued at approximately USD 35 billion in 2019 and is expected to grow, reflecting the enduring popularity of biscuits worldwide.

Tips for Perfect Biscuits

- Chill Your Dough: Refrigerating your dough before baking can help control the spread and create flakier biscuits.

- Use Cold Fat: Cold butter or shortening integrates better into the dough, ensuring those desirable layers.

- Handle with Care: Be gentle when mixing and shaping to avoid developing gluten, which can toughen the biscuits.

Conclusion

The biscuit making process is a rewarding culinary endeavor that can turn a few simple ingredients into a delectable treat. By mastering the steps of mixing, shaping, and baking, you can create biscuits that are the pride of any breakfast table or tea time spread.

Remember, practice makes perfect, so don’t be discouraged if your first batch isn’t picture-perfect. Keep experimenting with different flavors and techniques to find your biscuit bliss.

-

150 Auto starch less gummy candy depositing line: 60,000 gummies/h 280pcs of mold inside machine 8-10PH Cooling unit

-

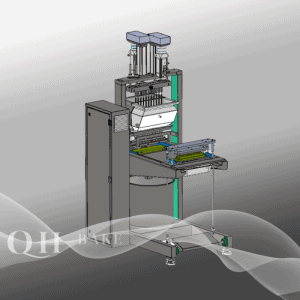

20S Servo-Form candy depositing Equipment: Cavity PCS: ±20; 100x80x160 Size(cm)

-

300 Auto starch less gummy candy depositing line 120,000 gummies/h 8-10PH Cooling unit 280pcs of twin-mold inside machine

-

50S Servo Control Candy Depositor: Servo; Cavity PCS: ±20; 200x100x170 Size(cm)

Call to Action

Ready to roll up your sleeves and get baking? Grab your apron, preheat your oven, and let’s make some biscuits! And as you perfect your biscuit making skills, share your creations and experiences with us. We’d love to see the fruits of your labor.

-

150 Auto starch less gummy candy depositing line: 60,000 gummies/h 280pcs of mold inside machine 8-10PH Cooling unit

-

20S Servo-Form candy depositing Equipment: Cavity PCS: ±20; 100x80x160 Size(cm)

-

300 Auto starch less gummy candy depositing line 120,000 gummies/h 8-10PH Cooling unit 280pcs of twin-mold inside machine

-

50S Servo Control Candy Depositor: Servo; Cavity PCS: ±20; 200x100x170 Size(cm)

-

600 Auto starch less gummy candy depositing line: 240,000 gummies/h 10-20 PH Cooling unit 520pcs of twin-mold inside machine

-

80 Automatic Gummy Candy Production Line: 40,000 gummies/h 5-8PH Cooling unit 200pcs of mold inside machine

-

Automatic Konjac Pearl Making Machine For Sales – Supplier & Manufacuture

-

Automatic Lollipop Production Line For Sale – Candy Machine Factory

-

Automatic Starch-less Depositing Production Line: Revolutionizing Candy Manufacturing