Last Updated on 06/10/2024 by QHBAKE

Hello, future gummy barons and confectionery connoisseurs! Are you ready to dive into the sweet, sometimes sticky, but always fascinating world of commercial gummy production?

If you’ve ever stared into the kaleidoscope of a gummy bear bag and wondered, “How many of these little guys can a gummy making machine actually churn out?” then you’re in the right place.

Let’s unwrap the layers of candy-coated mystery and discover the production capacity of a commercial gummy making machine.

The Mighty Gummy Making Machine

Picture this: a state-of-the-art, stainless-steel behemoth whirring to life on the factory floor. This isn’t just any machine; it’s your ticket to gummy domination. Commercial gummy making machines are designed with one goal in mind—to produce gummies, and lots of them. But what does “lots” actually mean? Well, that depends on a few factors, including the machine’s size, the complexity of the gummy shapes, and the efficiency of the operation.

Factors Influencing Production Capacity

Before we jump into numbers, it’s important to understand that the production capacity of a commercial gummy making machine isn’t set in stone. It’s influenced by several factors:

- Machine Size and Model: Bigger isn’t always better, but in the world of gummy production, a larger machine often means more gummies per hour.

- Gummy Shape and Complexity: Simple shapes like gummy bears can be produced faster than intricate, detailed shapes.

- Operational Efficiency: How smoothly the machine is run, maintained, and managed can significantly impact output.

- Staff Training: A well-trained team can optimize the machine’s performance, boosting production capacity.

The Numbers Game: Production Capacity Statistics

Now, let’s talk numbers. A small to medium-sized commercial gummy making machine can produce anywhere from 50 to 200 kilograms of gummies per hour. For larger, more automated machines, this number can soar to over 500 kilograms per hour. To put this in perspective, if each gummy bear weighs about 7 grams, a medium-sized machine could produce around 10,000 gummy bears in an hour!

According to a report by Global Industry Analysts, Inc., the global gummy confectionery market is expected to reach US$5.3 billion by 2025. That’s a lot of gummies, and a lot of potential for those with the machinery to produce them.

Maximizing Your Machine’s Potential

But how do you ensure your gummy making machine is working at its peak capacity? Here are a few tips:

- Regular Maintenance: A well-maintained machine is a happy machine. Keep it clean and calibrated to ensure it runs smoothly.

- Quality Ingredients: Use high-quality ingredients to avoid production hiccups and ensure consistent gummy quality.

- Optimize Processes: Streamline your production process to reduce downtime and increase efficiency.

- Staff Training: Invest in your team. A knowledgeable staff can operate the machine more effectively, leading to higher production.

The Future of Gummy Production

As technology advances, so does the efficiency and capacity of commercial gummy making machines. Innovations in automation, AI, and machine learning are paving the way for even greater production capabilities. Who knows? In a few years, we might be talking about machines that can produce personalized gummies on demand!

Conclusion

In the land of gummies, the production capacity of a commercial gummy making machine is the key to unlocking your sweet success. By understanding the factors that influence capacity, investing in the right machine, and optimizing your operation, you can ensure a steady stream of gummy goodness. Remember, the secret to gummy success is much like the recipe for a perfect gummy bear: a blend of the right ingredients, carefully mixed and expertly managed.

-

150 Auto starch less gummy candy depositing line: 60,000 gummies/h 280pcs of mold inside machine 8-10PH Cooling unit

-

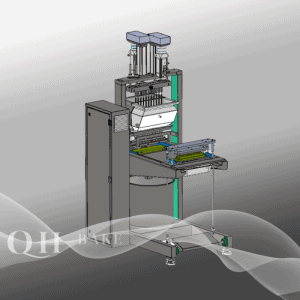

20S Servo-Form candy depositing Equipment: Cavity PCS: ±20; 100x80x160 Size(cm)

-

300 Auto starch less gummy candy depositing line 120,000 gummies/h 8-10PH Cooling unit 280pcs of twin-mold inside machine

-

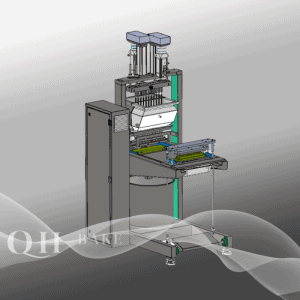

50S Servo Control Candy Depositor: Servo; Cavity PCS: ±20; 200x100x170 Size(cm)

Call to Action

Ready to ramp up your gummy production? Look out for our next article where we’ll explore the latest trends in commercial gummy making machines and how you can stay ahead of the curve. And as you embark on your gummy venture, remember to keep it sweet, keep it clean, and most importantly, keep it fun.

-

150 Auto starch less gummy candy depositing line: 60,000 gummies/h 280pcs of mold inside machine 8-10PH Cooling unit

-

20S Servo-Form candy depositing Equipment: Cavity PCS: ±20; 100x80x160 Size(cm)

-

300 Auto starch less gummy candy depositing line 120,000 gummies/h 8-10PH Cooling unit 280pcs of twin-mold inside machine

-

50S Servo Control Candy Depositor: Servo; Cavity PCS: ±20; 200x100x170 Size(cm)

-

600 Auto starch less gummy candy depositing line: 240,000 gummies/h 10-20 PH Cooling unit 520pcs of twin-mold inside machine

-

80 Automatic Gummy Candy Production Line: 40,000 gummies/h 5-8PH Cooling unit 200pcs of mold inside machine

-

Automatic Konjac Pearl Making Machine For Sales – Supplier & Manufacuture

-

Automatic Lollipop Production Line For Sale – Candy Machine Factory

-

Automatic Starch-less Depositing Production Line: Revolutionizing Candy Manufacturing