In the world of candy, soft candy is highly cherished by consumers for its unique flavors and appealing shapes. The key equipment for producing soft candy is undoubtedly starch mold candy production equipment. Today, we present a semi-automatic starch mold candy production machine specifically designed for small production enterprises, which will boost your candy business.

A Perfect Fusion of Traditional Craftsmanship and Modern Technology

This equipment utilizes a traditional plug-in pouring method, a mature and reliable process that has stood the test of time. It ensures that the soft candy maintains consistent quality during the molding process, resulting in each candy having a uniform taste and exquisite appearance. Here, the stability of traditional craftsmanship meets the efficiency of modern technology. Thanks to the advanced touch screen control system, adjusting candy size is effortless. Whether you are producing small, cute mini soft candies or slightly larger specialty candies, you can easily set the desired size on the touch screen to meet different customer needs and adapt to a diverse market.

Compact Design, Flexible Layout

For small production enterprises, space is often a precious commodity. This equipment measures only 4-5 meters in length, significantly reducing the footprint compared to larger production lines. This compact design allows you to easily conduct candy production without requiring a large factory space. It can be flexibly positioned in tight areas, whether in a corner of the factory or next to a narrow passageway. The streamlined body design not only saves space but also simplifies operation and maintenance, making your production process more efficient and seamless.

Focusing on Small Businesses for a Sweet Start

We understand the potential and needs of small businesses in the candy market. This semi-automatic starch mold candy production equipment is developed with a deep understanding of small business customers. It is designed to provide an affordable, efficient, and reliable production solution for those in the startup phase or those looking to expand their product lines. Whether it’s for home-based candy making or small candy factory production needs, this equipment is an ideal fit. It will help you launch your sweet business at a lower cost, quickly enter the market, seize opportunities, gradually expand production capacity, and achieve sustainable growth in candy production. Choosing our semi-automatic starch mold candy production equipment means choosing a path to sweet success. With its outstanding performance, flexible design, and thoughtful attention to the needs of small businesses, it will help you excel in the candy market, making each soft candy a testament to your business’s achievements.

In addition to making jelly candies, this equipment can also produce various starch-based products, including real liquid chocolate cores, relatively viscous candy cores like Skittles, and starch-based wafer sugar balls such as Mylikes.

Starch Mold Production Process:

Cooking Process

The starch mold production process involves several critical steps to ensure the proper preparation of the syrup mixture, which is essential for producing high-quality starch mold candies. Here is a detailed breakdown of the cooking process:

The cooking process is designed to heat and melt the various ingredients, such as syrups, starches, and colloids, to create a homogeneous mixture suitable for starch mold candy production. This process is crucial for achieving the desired texture and consistency of the final product.

Step 1: Melting Syrup, Sugar Water, and Starch in the First Cooker

- Objective : To dissolve and melt the primary ingredients, including syrup, sugar water, and starch.

- Process :

- The first cooker is equipped with steam or jacket heating to provide the necessary heat.

- The ingredients are added to the cooker and heated until they reach a uniform, molten state.

- This step ensures that the sugars and starches are fully dissolved and mixed, creating a smooth base for the candy.

Step 2: Melting Gum Base (e.g., Pectin, Gelatin, Agar-Agar) in Another Cooker

- Objective : To melt and prepare the gum base at a lower temperature to prevent degradation of the colloids.

- Process :

- A separate cooker is used to melt the gum base, such as pectin, gelatin, or agar-agar.

- The temperature is carefully controlled to ensure that the colloids are fully dissolved without breaking down their structural properties.

- This step is critical for achieving the desired elasticity and texture in the final candy.

Step 3: Mixing the Finished Product into the Second Tank

- Objective : To combine the melted syrup and gum base into a single homogeneous mixture.

- Process :

- The contents of the first and second cookers are transferred to a mixing tank.

- The mixture is stirred until it reaches the desired consistency and temperature, as specified by the set data.

- This step ensures that all ingredients are thoroughly combined, resulting in a uniform syrup ready for the next stage.

Step 4: Transferring the Ready Syrup into the Buff/Storage Tank

- Objective : To store the prepared syrup at a controlled temperature until it is ready for the next stage of production.

- Process :

- The finished syrup is transferred to a buff or storage tank using pumps and heating pipelines.

- The tank is designed to maintain the syrup at the set temperature, ensuring it remains in a workable state for the subsequent steps.

Equipment and Materials

- Cookers : The cookers are made of high-quality stainless steel, with the option to use 316-grade stainless steel for food contact parts, which offers superior corrosion resistance compared to 304-grade steel.

- Electrical Appliances : All electrical components, including control panels and temperature sensors, are sourced from reputable brands such as Siemens.

- Temperature Control : The temperature control system is provided by Omron, ensuring precise and reliable temperature management throughout the cooking process.

- Pipes and Pumps : The pipelines and pumps are insulated with jacketed insulation to maintain the syrup at the desired temperature during transportation. This ensures that the syrup remains at a consistent temperature, preventing it from cooling down or solidifying before it reaches the next stage.

Advantages of the Cooking Process

1. Precision and Consistency : The use of high-quality materials and reliable temperature control systems ensures that the cooking process is precise and consistent, resulting in a uniform syrup mixture.

2. Flexibility : The ability to adjust temperatures and mixing times allows for the production of various types of candies with different textures and properties.

3. Hygiene and Safety : The use of stainless steel and well-known brands for electrical components ensures that the equipment is durable, easy to clean, and safe for food production.

4. Energy Efficiency : The insulated pipelines and pumps help maintain the syrup's temperature, reducing energy consumption and ensuring efficient operation.

By following this detailed cooking process, manufacturers can produce high-quality starch mold candies that meet the highest standards of taste, texture, and consistency.

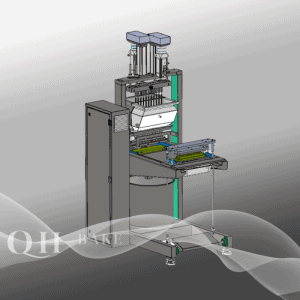

Starch Molding process

The starch molding equipment is a critical component in the production of starch mold candies, ensuring that the molds are created with precision and consistency. This equipment is specifically designed to handle starch as the primary material, transforming it into perfectly shaped molds for the subsequent candy production process.

Key Features of the Starch Molding Equipment

1. Starch Distribution System

- Objective : To evenly distribute starch onto the molding plate.

- Process :

- Starch is delivered to the equipment via an elevator system, which ensures a consistent supply of material.

- Once the starch reaches the equipment, it is spread evenly across the molding plate. This is achieved through a combination of mechanical and vibrational techniques.

- A vibration device is integrated into the system to ensure that the starch is uniformly distributed. The vibrations help to settle the starch particles evenly, eliminating any clumps or uneven areas.

- A scraper mechanism is also employed to further ensure that the starch is properly positioned on the plate. The scraper moves across the surface of the plate, smoothing out the starch layer and ensuring a consistent thickness.

2. Automated Linkage with Depositing Machine

- Objective : To achieve seamless integration and automation in the production process.

- Process :

- The starch molding equipment is designed to be connected in-line with the depositing machine. This connection allows for an automated linkage, where the starch molds are prepared and then directly fed into the depositing machine.

- The automated linkage ensures that the production process is continuous and efficient, reducing downtime and increasing overall productivity.

- This integration also helps in maintaining a consistent workflow, as the molds are prepared and filled with syrup in a synchronized manner.

3. Material and Construction

- Objective : To ensure durability, hygiene, and ease of maintenance.

- Process :

- The entire machine is constructed from high-quality stainless steel 304. This material is chosen for its excellent corrosion resistance, durability, and ease of cleaning.

- Stainless steel 304 is particularly suitable for food processing equipment, as it meets the stringent hygiene standards required in the industry.

- The use of stainless steel also ensures that the equipment can withstand the rigors of continuous operation, providing long-term reliability and minimal maintenance requirements.

Advantages of the Starch Molding Equipment

1. Precision in Mold Creation : The combination of the vibration device and scraper ensures that the starch is evenly distributed and positioned on the molding plate. This precision is crucial for creating molds with consistent shapes and sizes, which in turn ensures uniform candy production.

2. Efficiency and Productivity : The automated linkage with the depositing machine streamlines the production process, reducing manual intervention and increasing overall efficiency. This results in higher productivity and reduced labor costs.

3. Hygiene and Safety : The use of stainless steel 304 ensures that the equipment meets the highest hygiene standards. This material is easy to clean and resistant to contamination, making it ideal for food processing applications.

4. Durability and Longevity : Stainless steel 304 is known for its durability and resistance to wear and tear. This ensures that the equipment remains in optimal working condition for an extended period, reducing the need for frequent replacements or repairs.

5. Ease of Integration : The equipment is designed to be easily integrated into existing production lines. Its modular design and compatibility with other machines make it a versatile addition to any candy production facility.

Conclusion

The starch molding equipment is a vital component in the production of starch mold candies, offering precision, efficiency, and reliability. By ensuring even starch distribution, seamless integration with the depositing machine, and high-quality construction, this equipment helps manufacturers achieve consistent and high-quality candy production. Whether you are a small-scale producer or a large-scale manufacturer, our starch molding equipment is designed to meet your needs and enhance your production capabilities.

shapes/molds printing on the starch molding process

Shapes/Molds Printing on the Starch Mold System

The starch mold system is a highly efficient and versatile solution for creating intricate and precise molds for candy production. A key component of this system is the die-stamping equipment, which plays a crucial role in imprinting the desired shapes and patterns onto the starch molds. Here’s a detailed overview of how this process works and the features that make it stand out:

Die-Stamping Equipment: Precision and Automation

1. Automatic Plate Detection and Positioning

- Objective : To ensure accurate and consistent embossing of patterns onto the starch molds.

- Process :

- The die-stamping equipment is equipped with advanced sensors that automatically detect the presence and position of the molding plate.

- These sensors ensure that the embossing process is precisely aligned, preventing any misalignment or errors in the pattern imprinting.

- The automated detection system enhances efficiency and reduces the risk of human error, ensuring that each mold is accurately shaped.

2. Vibration Device to Prevent Sticking

- Objective : To prevent the mold from sticking due to starch residue.

- Process :

- A vibration device is integrated into the die-stamping equipment. This device gently vibrates the mold plate during the embossing process.

- The vibrations help to release any starch that might stick to the mold, ensuring a smooth and clean separation after the imprinting process.

- This feature is crucial for maintaining the quality and consistency of the molds, reducing downtime for cleaning and maintenance.

3. Easy Mold Changeover

- Objective : To allow customers to switch between different mold designs quickly and easily.

- Process :

- The mold plate is designed to be easily replaceable. When a customer needs to change the mold, they can simply swap out the mold plate without the need for extensive reconfiguration or downtime.

- This flexibility allows manufacturers to produce a wide variety of candy shapes and sizes, catering to diverse market demands and seasonal requirements.

Mold Plate Specifications

1. Dimensions

- Size : The mold plate measures 400 cm x 600 cm.

- Impact : This large size allows for high production capacities, making it suitable for both small-scale and large-scale candy production.

2. Material and Coating

- Material : The mold plate is constructed from high-quality stainless steel.

- Coating : The plate is coated with Teflon, a non-stick material that prevents starch from adhering to the surface.

- Surface Texture : The plate features a rough surface, which enhances its functionality by providing better grip and release properties during the molding process.

3. Production Capacity

- Variability : The production capacity of the mold plate varies based on the type of candy being produced. Different candy shapes and sizes will influence the number of molds that can be created per plate.

- Efficiency : The large size and efficient design of the mold plate ensure high throughput, allowing manufacturers to produce a significant volume of candies in a short period.

Advantages of the Starch Mold System

1. Precision and Consistency : The die-stamping equipment ensures that each mold is precisely shaped, resulting in uniform and high-quality candy products.

2. Efficiency and Productivity : The automated detection and vibration features enhance the efficiency of the molding process, reducing downtime and increasing overall productivity.

3. Flexibility : The easy mold changeover allows manufacturers to quickly switch between different candy shapes and sizes, catering to diverse market demands.

4. Hygiene and Durability : The stainless steel construction and Teflon coating ensure that the mold plate is durable, easy to clean, and resistant to wear and tear.

5. Scalability : The large mold plate size supports both small-scale and large-scale production, making it suitable for a wide range of manufacturing needs.

Conclusion

The starch mold system, with its advanced die-stamping equipment and high-quality mold plates, offers a comprehensive solution for candy manufacturers. It combines precision, efficiency, and flexibility, ensuring that manufacturers can produce a wide variety of high-quality candies with ease. Whether you are looking to expand your product line or improve your production efficiency, our starch mold system is designed to meet your needs and enhance your manufacturing capabilities.

Depositing/pouring syrup process

Capacity:150kg/h

Trays size:400x600mm

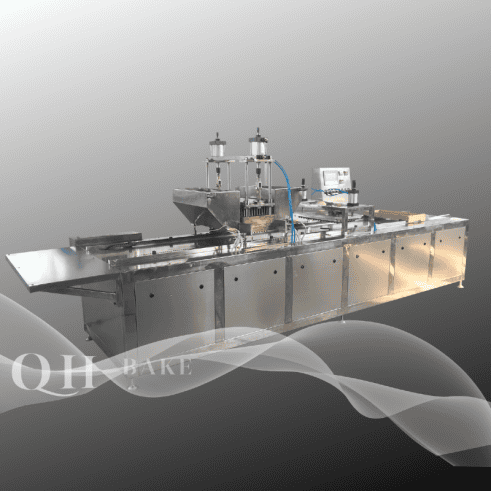

Candy depositing machine

The semi-automatic starch mold depositing pouring equipment is a versatile and efficient solution designed to streamline the syrup pouring process in candy production. This equipment has been upgraded to offer enhanced functionality, reduced complexity, and improved cost-effectiveness. Here’s a detailed overview of its features and benefits:

Key Features and Upgrades

1. Reduced Component Count and Compact Design

- Objective: To simplify the equipment and reduce its footprint.

- Process:

- The design has been optimized to require fewer components, making the equipment more straightforward to operate and maintain.

- The compact design allows the equipment to take up less space compared to traditional starch mold machines, making it ideal for facilities with limited space.

- Despite its smaller size, the equipment maintains high functionality and efficiency, ensuring that production capacity is not compromised.

2. Competitive Pricing

- Objective: To offer a cost-effective solution without sacrificing quality.

- Process:

- The streamlined design and reduced component count contribute to a more competitive price point.

- This makes the equipment accessible to a broader range of customers, including small-scale producers and laboratory settings.

3. Flexible depositing Capacity

- Objective: To accommodate different production scales.

- Process:

- The equipment can be designed to pour a large number of candies at once, depending on the size of the mold plate.

- This flexibility ensures that the equipment can meet the needs of both laboratory-scale testing and small-scale production runs.

- The pouring capacity can be easily adjusted to match the specific requirements of each production batch.

4. Precision depositing Control

- Objective: To ensure consistent syrup deposition.

- Process:

- The pouring rod is made of high-quality stainless steel 304, ensuring durability and resistance to corrosion.

- The amount of syrup poured is precisely controlled by a cylinder or servo mechanism.

- When changing the type of product, only the settings need to be adjusted, allowing for quick and easy customization.

5. Safety and Induction Technology

- Objective: To enhance user safety and operational reliability.

- Process:

- The pouring head is equipped with induction sensors that detect the presence of the mold plate.

- The pouring head only moves when the mold plate is sensed, preventing accidental movements and ensuring the safety of the operator.

- This feature also ensures that syrup is only deposited into the correct molds, reducing waste and improving overall efficiency.

Advantages of the Semi-Automatic Starch Mold Depositing Pouring Equipment

1. Efficiency and Space-Saving: The compact design and automated starch handling reduce the need for manual labor and minimize the equipment’s footprint.

2. Cost-Effectiveness: The streamlined design and competitive pricing make this equipment an attractive option for small-scale producers and laboratories.

3. Flexibility and Customization: The ability to adjust the pouring capacity and syrup amount allows for a wide range of production needs, from small batches to larger runs.

4. Hygiene and Durability: The use of stainless steel 304 ensures that the equipment is easy to clean and resistant to wear and tear, maintaining high hygiene standards.

5. Safety and Reliability: The induction technology ensures safe operation by preventing accidental movements and ensuring precise pouring into the molds.

Conclusion

The semi-automatic starch mold depositing pouring equipment is a highly efficient and versatile solution for syrup pouring in candy production. Its compact design, automated features, and precision control make it an ideal choice for both small-scale producers and laboratory settings. By offering a cost-effective, flexible, and reliable solution, this equipment helps manufacturers achieve high-quality candy production with ease. Whether you are conducting research or producing small batches of candies, our depositing pouring equipment is designed to meet your needs and enhance your production capabilities.

Drying Process

The Application of the Drying Room in Candy Production

The drying room is a crucial piece of equipment used to remove moisture from jelly candy during the candy production process. It ensures that the candy reaches an ideal drying state by controlling conditions such as temperature and humidity. In the starch mold production line, starch helps to dry the candies until they are ready for demolding.

To facilitate transportation and reduce labor intensity, customers can use forklifts or cranes to move the candies. At the same time, QHBake can also design a fully automatic drying and conveying system to further enhance production efficiency and automation.

The Importance of the Drying Room

The drying room plays a vital role in candy production, mainly reflected in the following aspects:

- Ensuring Product Quality: By precisely controlling temperature and humidity, the drying room ensures consistent quality of the candies during the drying process, avoiding defects caused by excessive or insufficient moisture.

- Improving Production Efficiency: Automated drying and conveying systems reduce manual intervention, increase production efficiency, and lower labor intensity.

- Flexibility and Scalability: The drying room can be adjusted according to different candy types and production scales to meet diverse production needs.

- Sustainability and Energy Efficiency: By optimizing the drying process and reducing energy consumption and carbon emissions, the drying room contributes to more environmentally friendly production.

QHBake's Solutions

QHBake's fully automatic drying and conveying system features:

- High Degree of Automation: The system can achieve full automation from candy forming to drying and conveying, reducing manual operations and increasing production efficiency.

- Customized Design: Based on specific customer needs, QHBake can tailor the drying and conveying system to meet different production scales and product types.

- Energy Efficiency: With advanced drying technology, combined with heavy insulation design and precise process control, QHBake's drying room can ensure product quality while reducing energy consumption.

By leveraging these advanced technologies and equipment, QHBake helps candy manufacturers improve production efficiency, product quality, and market competitiveness.

De-starch

Innovative Vacuum Negative Pressure Powder Removal System

After the candy has dried, it is essential to separate it from the starch. This process traditionally generates significant waste and dust. To address these challenges, we have developed a new vacuum negative pressure powder removal design that offers several improvements over the conventional rotary method.

Key Features of the Vacuum Negative Pressure Powder Removal System

1. Quieter and More Space-Efficient Operation

- Objective: To reduce noise levels and minimize the equipment's footprint.

- Process:

- The vacuum negative pressure system operates more quietly compared to traditional rotary methods, creating a more pleasant working environment.

- The design is more compact, taking up less space while maintaining high efficiency, making it suitable for facilities with limited space.

2. Reduced Dust Production

- Objective: To minimize dust generation during the powder removal process.

- Process:

- The vacuum system effectively captures and removes starch powder with minimal dispersion, resulting in less dust in the working area.

- This not only improves the cleanliness of the production environment but also enhances worker safety and product quality.

3. Airtight Connections and Efficient Powder Recycling

- Objective: To ensure efficient powder collection and recycling.

- Process:

- Each connection in the system is designed to be as airtight as possible, preventing leaks and ensuring that all starch powder is captured.

- The collected powder is transported back to the front of the system using a screw conveyor, allowing for efficient recycling and reuse of the starch.

4. Automated Conveying and Powder Removal

- Objective: To automate the entire process for increased efficiency.

- Process:

- The system is fully automated, ensuring consistent and reliable operation without the need for manual intervention.

- Candies are conveyed in a single direction, making it easy for customers to collect them at the exit.

- Alternatively, the candies can be sent directly to the next step in the production process or to packaging via a conveyor belt, streamlining the workflow.

5. High-Quality Construction and Hygienic Design

- Objective: To ensure durability, hygiene, and ease of maintenance.

- Process:

- The equipment is constructed from high-quality stainless steel, ensuring durability and resistance to corrosion.

- A sandblasting surface treatment can be selected to reduce gaps and eliminate sanitary dead corners, enhancing the equipment's hygiene.

- All motors and electrical appliances are sourced from well-known brands such as Siemens, ensuring reliability and performance.

Advantages of the Vacuum Negative Pressure Powder Removal System

1. Enhanced Environmental Control: The system significantly reduces dust and noise, creating a cleaner and quieter working environment.

2. Efficiency and Productivity: The automated process and efficient powder recycling minimize downtime and improve overall production efficiency.

3. Hygiene and Safety: The airtight design and high-quality materials ensure that the equipment meets the highest hygiene standards, reducing the risk of contamination.

4. Space-Saving Design: The compact footprint of the system makes it suitable for facilities with limited space, without compromising functionality.

5. Reliability and Durability: The use of well-known brands for motors and electrical components ensures the system's reliability and long-term performance.

Conclusion

Our innovative vacuum negative pressure powder removal system offers a significant upgrade over traditional methods, providing a quieter, more efficient, and hygienic solution for separating candies from starch. By automating the process and ensuring efficient powder recycling, this system enhances production efficiency, worker safety, and product quality. Whether you are looking to improve your current production line or invest in new equipment, our system is designed to meet your needs and enhance your manufacturing capabilities.

Last step: Surface Processing: Creating a Feast for the Eyes and Taste Buds

In the world of confectionery, surface processing is not just about aesthetics; it's about enhancing the overall quality and consumer experience of the product. We understand this well, which is why we have meticulously designed two advanced process flows for candy surface treatment: wax/oil coating and sugar sanding. Together, they provide candies with an enchanting outer layer, turning each piece into a feast for both the eyes and the taste buds.

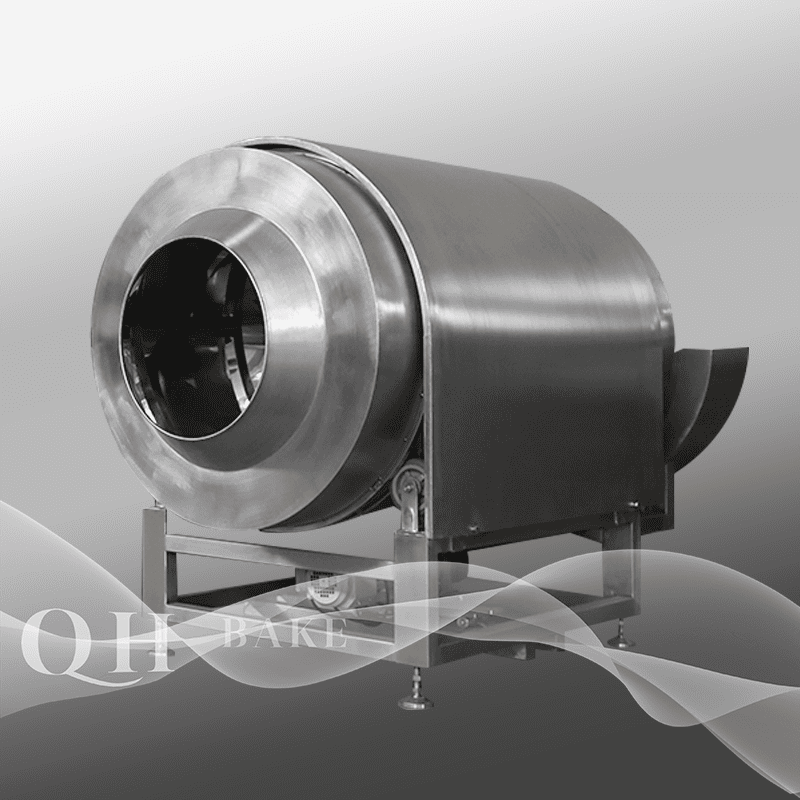

Wax/Oil Coating Drum: A Perfect Blend of Shine and Protection

Our wax/oil coating process is a crucial step in candy surface treatment. We use an advanced wax/oil machine to evenly spray edible oil and wax onto the surface of the candies. The continuous rotation of the equipment ensures that these materials are uniformly distributed, forming a smooth, glossy, and protective layer on the candy surface. This not only makes the candies more visually appealing but also effectively prevents damage from friction during storage and transportation, extending their shelf life.

The design of the wax/oil machine takes automation and hygiene into full consideration. The machine is equipped with an internal screw mechanism that automatically feeds the candies in and out, ensuring an efficient and stable processing flow. To ensure product hygiene, we manufacture the equipment using 304 stainless steel, a material known for its excellent corrosion resistance and ease of cleaning, meeting the strict hygiene standards of the food processing industry. Additionally, the machine features a reversible function for easy cleaning and maintenance, ensuring that the equipment remains in optimal working condition at all times.

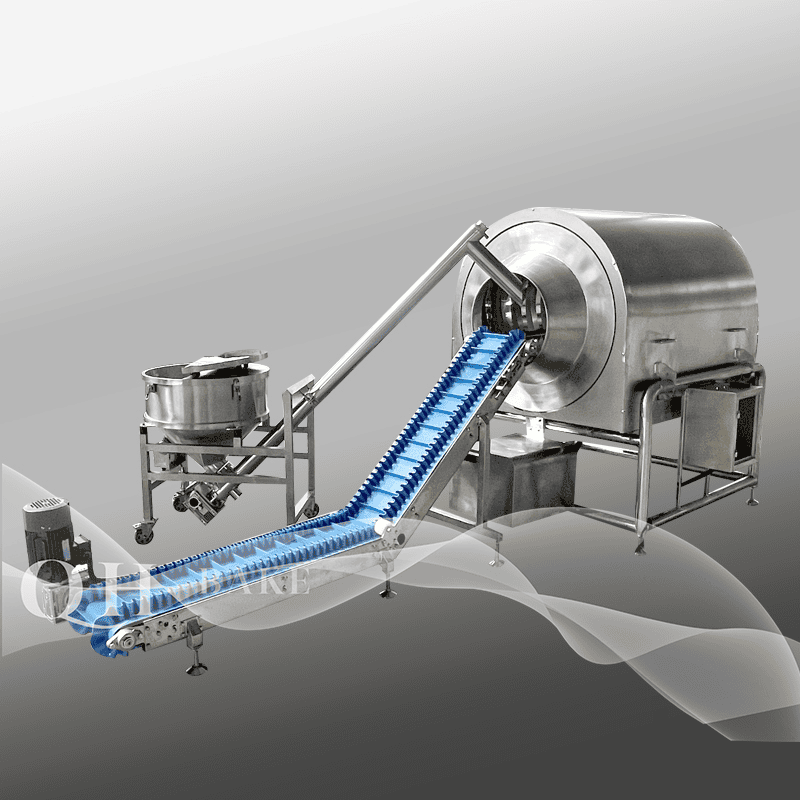

Sugar Sanding Drum : Enhancing Texture and Flavor

Sugar sanding is another highlight of our candy surface treatment process. We use fine sugar particles to evenly coat the surface of jelly candies, ensuring that the sugar particles adhere uniformly. This process not only enhances the visual appeal of the candies but also significantly improves the taste experience when chewing. The sugar particles gradually dissolve in the mouth, releasing a sweet flavor while effectively preventing the candies from sticking together, ensuring that each piece maintains its individual shape.

The brilliance of the sugar sanding process lies in the precise control of sugar particle size and distribution. Using advanced equipment and technology, we ensure that each candy is evenly coated with sugar, neither too much nor too little. This just-right sugar coating not only enhances the texture of the candy but also adds a unique flavor. Whether it's fruity candies with a tangy sweetness or rich, chocolate-flavored candies, the sugar coating perfectly complements the core flavor, creating an unforgettable taste experience.

Dressing Candies in an Enchanting Outer Layer and Initiating a Sweet Taste Journey

Candy surface processing is a vital part of the production process, as it affects not only the appearance and texture of the candies but also directly influences consumer purchasing decisions. Through our carefully designed wax/oil coating and sugar sanding processes, we dress each candy in an enchanting outer layer, turning them into a feast for both the eyes and the taste buds.

The wax/oil coating process gives candies a smooth, glossy surface, enhancing their visual quality while providing effective protection. The sugar sanding process, on the other hand, sprinkles fine sugar particles on the candy surface, releasing a rich sweetness when chewed and preventing the candies from sticking together. The combination of these two processes not only makes the candies more visually appealing but also offers a unique experience in terms of texture and flavor.

We are always committed to providing high-quality candy production equipment and solutions. Our wax/oil and sugar sanding machines are designed with advanced technology to ensure that every step of candy surface processing achieves the best results. Whether you are a large-scale candy manufacturer or a small candy workshop, our equipment can meet your needs and help you produce candies that are visually stunning and rich in flavor.

Choose our candy surface processing equipment and let your candies stand out in the competitive market, initiating a sweet taste journey.