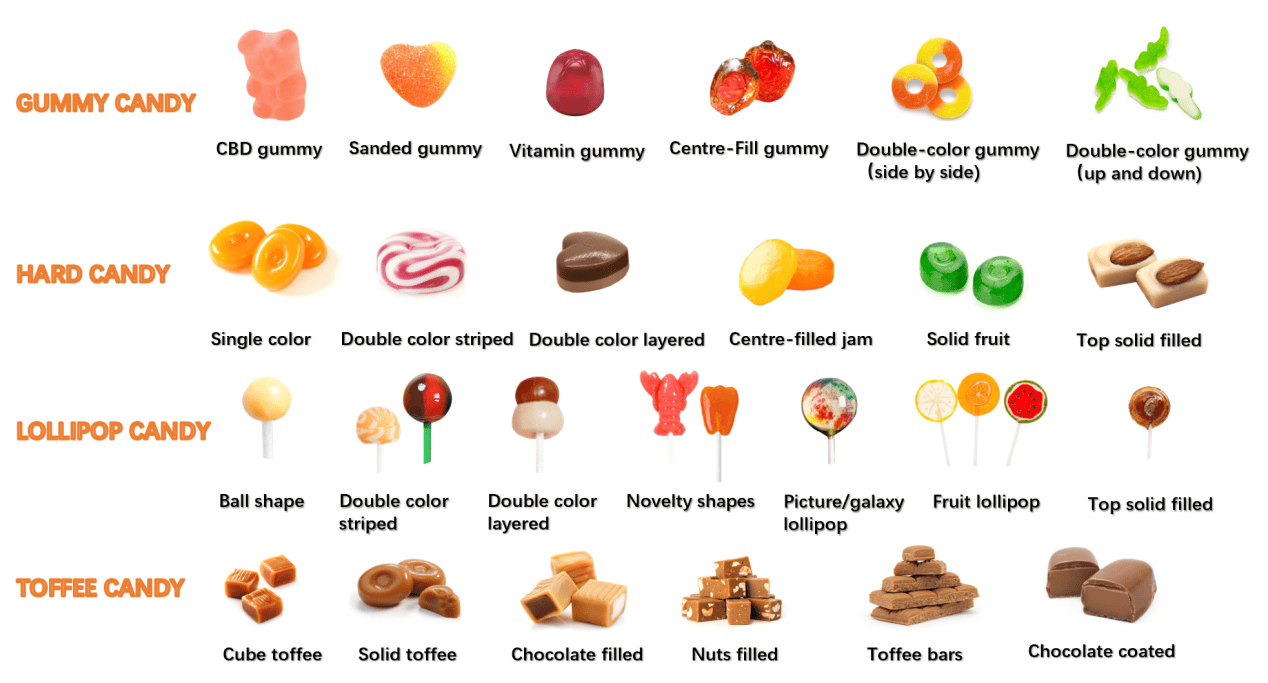

QHBake specializes in manufacturing high-performance gummy, candy, and biscuit production line machines. Our solutions feature advanced systems like cooking, depositing, and cooling for efficient, consistent results. With customizable options such as the Automatic CFA System and Sugar Sanding Coater, we meet diverse production needs. Built with durable stainless steel and enhanced safety features, our machines ensure reliability, low maintenance, and operator protection. QHBake combines innovation and quality to deliver efficient, reliable equipment for modern confectionery manufacturing.

Parameters

| Model | 80 | 150 | 300 | 450 | 600 |

| Produktionskapacitet | 80KG/H | 150KG/H | 300 kg/t | 450KG/H | 600 kg/t |

| Max slik vægt | 2-8g/or more customized | 2-8g/or more customized | 2-8g/or more customized | 2-8g/or more customized | 2-8g/or more customized |

| Elektrisk strøm | 25kw/380v | 32kw/380v | 39kw/380v | 48kw/380v | 75kw/380v |

| Total længde | 7m | 17m | 17m | 18m | 18m |

| Mould quantity | 160pcs | 240pcs | 480pcs | 720pcs | 960pcs |

1.Cooking system

The cooking system is a crucial component of the production line, consisting of a high-efficiency jacketed cooker and a versatile storage tank. The jacketed cooker is engineered to rapidly dissolve sugar and maltose, achieving a consistent and uniform solution through advanced heat transfer technology. This ensures that the mixture is fully prepared for subsequent processes, saving time and enhancing production efficiency.

The storage tank complements the system by serving as a reservoir for the cooked liquid. It is specifically designed to regulate and reduce the liquid's temperature, maintaining its quality and stability. This step is essential to ensure the liquid is at the optimal temperature for downstream operations, preventing thermal degradation and preserving the desired product characteristics.

Together, the jacketed cooker and storage tank form a seamless, efficient cooking system tailored to meet the demands of modern confectionery and bakery production lines.

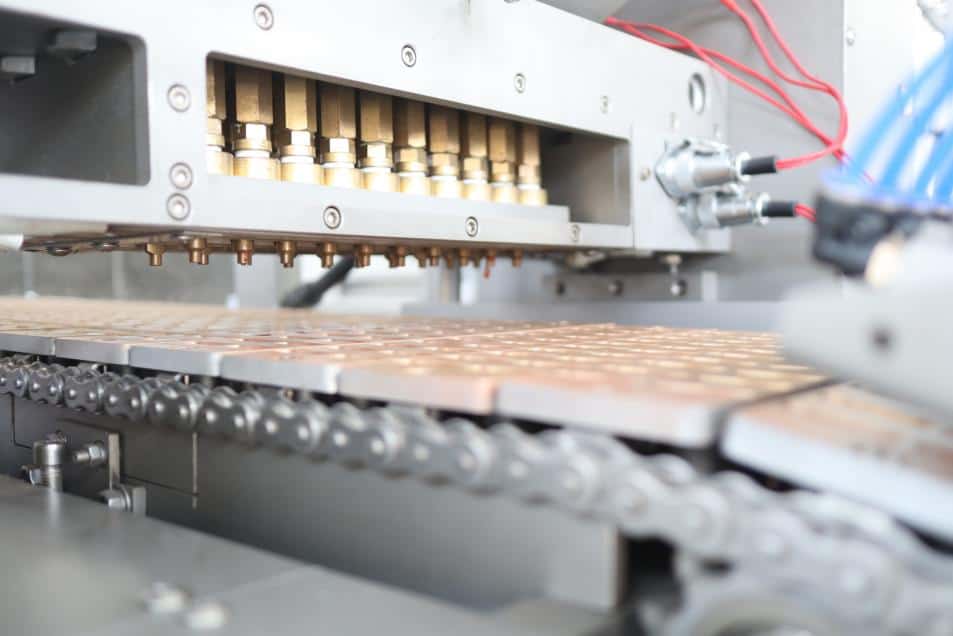

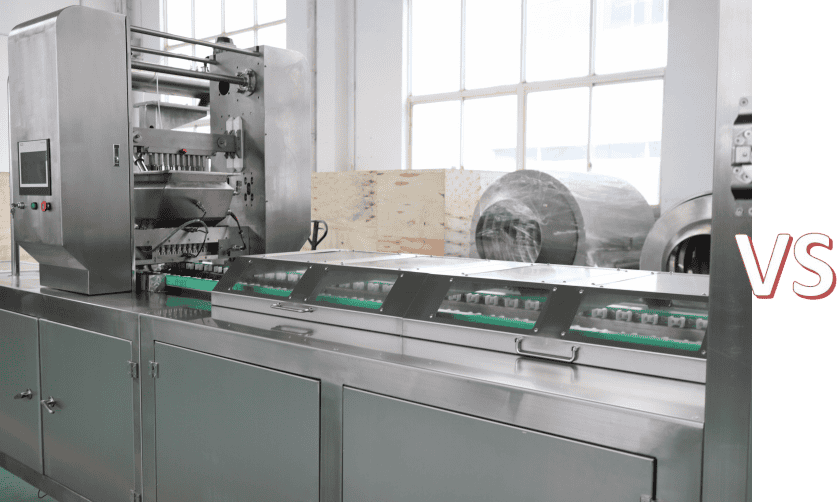

2.Depositing system

The depositing system is designed with precision and efficiency to ensure consistent quality in every candy piece. Its high-accuracy fabrication technology, particularly in the deposit piston and copper components, guarantees uniform candy weight, minimizing deviations and ensuring product consistency across large production batches.

A flavor and color mixer is integrated into the system, allowing for the efficient and thorough blending of flavors, colors, and other essential ingredients. This ensures that each candy has a vibrant appearance and a uniform taste profile, meeting high-quality standards.

Additionally, the system includes an oil-spraying machine that lightly coats the candy molds, significantly improving the demolding process. This feature not only enhances production efficiency but also ensures that the candies retain their shape and finish, reducing the risk of damage or defects during removal.

The depositing system is a key element of the production line, combining precision engineering and thoughtful design to meet the demands of high-capacity confectionery manufacturing.

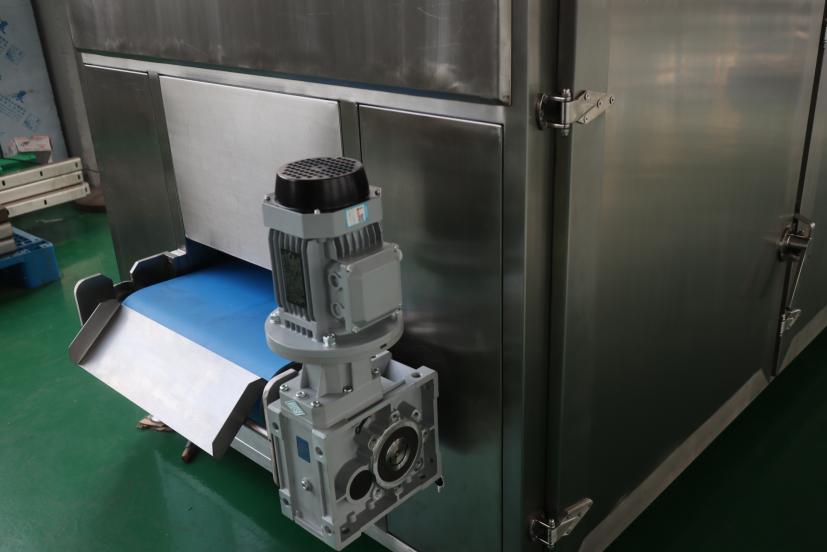

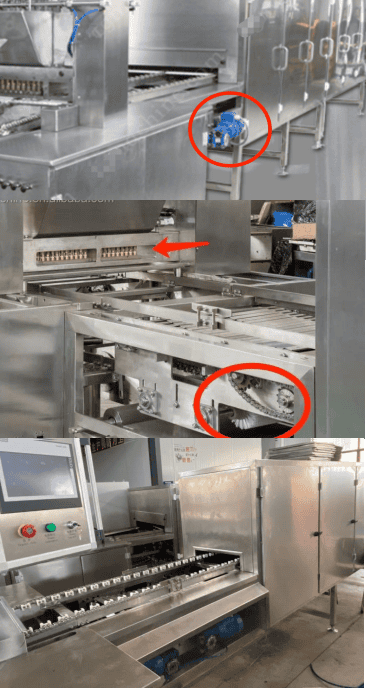

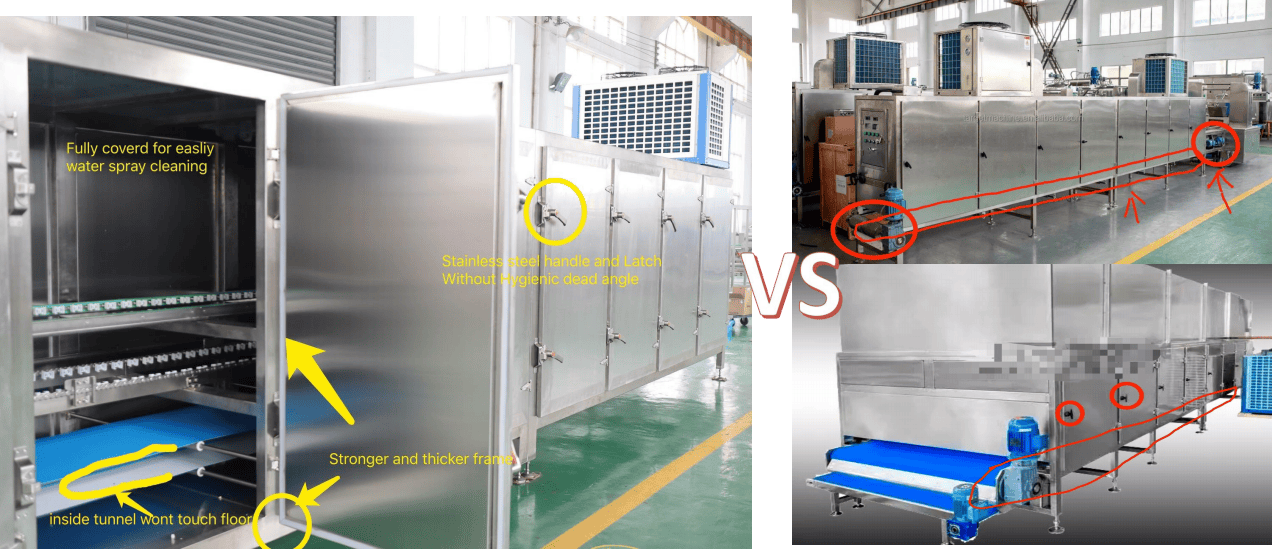

3.Cooling system

The cooling system is an essential component of the production line, specifically designed to rapidly and efficiently reduce the temperature of the candy. By ensuring precise cooling, it helps maintain the structural integrity, texture, and overall quality of the final product.

Built for durability and stability, the cooling system operates with low noise, ensuring a quiet and smooth production environment. Its robust construction features a frame with a superior thickness compared to industry standards, offering enhanced strength and longevity. While many factories use frames with 1mm or 2mm thickness, this system’s reinforced frame provides greater reliability and resistance to wear, even under continuous operation.

With its advanced design and exceptional performance, the cooling system not only extends the equipment's service life but also ensures stable and efficient production, meeting the high demands of modern confectionery manufacturing.

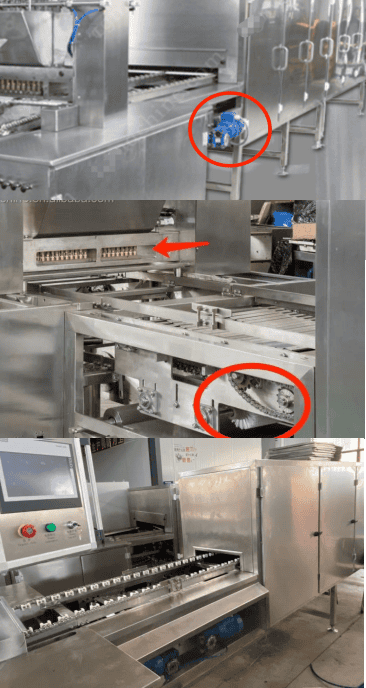

4.Automatic CFA System

The Automatic CFA (Color, Flavor, and Acid) System is a critical component in modern confectionery production, designed to streamline and enhance the post-cooking process. Once the material is cooked, it is automatically transferred to the CFA tanks, where precise and consistent mixing takes place.

QHBake’s advanced automatic CFA system is tailored to meet customer-specific requirements, offering seamless integration for adding color, flavor, and acid to the product. This system ensures accurate dosing and thorough blending, resulting in a uniform distribution of ingredients that enhances both the appearance and taste of the final product.

Engineered for efficiency and precision, the system minimizes manual intervention while maintaining consistent quality, even in high-capacity production lines. By automating the process of ingredient addition, the Automatic CFA System reduces labor costs, enhances production efficiency, and ensures the final product meets exacting quality standards.

This customizable system reflects QHBake's commitment to innovation, delivering solutions that align with the unique needs of every customer.

5.Sugar sanding coater

The Sugar Sanding Coater is an advanced system designed for efficient and hygienic sugar-coating processes, ideal for a variety of confectionery products. Equipped with a screw-type tank, it ensures automatic material transfer in and out, streamlining operations and reducing manual handling.

With its larger diameter design, the coater offers increased capacity, making it suitable for high-volume production while maintaining uniform coating quality. The system is engineered with forward and reverse control functions, which significantly simplify cleaning procedures and enhance overall equipment maintenance.

Hygiene is a top priority in the design of the Sugar Sanding Coater. It features minimal sanitary dead spaces, reducing the risk of residue buildup and ensuring compliance with stringent food safety standards. Additionally, the system operates with low noise levels, creating a quieter and more comfortable production environment.

Built with a robust stainless steel pipe rack, the coater combines durability with ease of cleaning and corrosion resistance, ensuring long-term performance and reliability. This system is the perfect solution for manufacturers seeking efficiency, precision, and high-quality results in sugar-coating applications.

6.Oil polishing coater

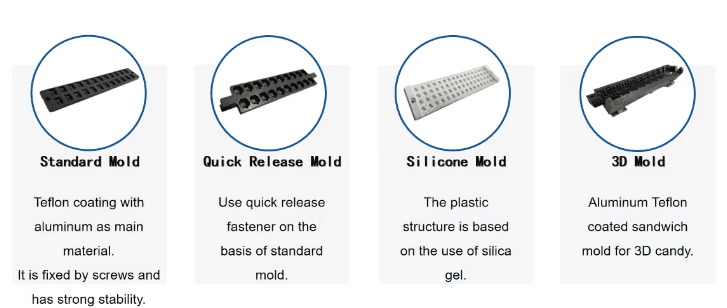

7.MouldS

The moulds are meticulously designed to deliver precision and efficiency in the production process. Each set includes 300 pieces, with 10 additional pieces in reserve to ensure seamless production without interruptions.

Key Features:

- Materiale: Crafted from high-quality aluminum alloy using advanced die-forming techniques, the moulds are coated with Teflon to provide excellent non-stick properties.

- Customization: The shape of the moulds can be fully customized based on customer requirements. Our engineers carefully design the arrangement of the moulds to maximize production efficiency and ensure optimal results.

- Die-Cast Construction: The moulds are constructed with durable copper alloy and treated with anti-sticking coatings, ensuring smooth operation and minimal residue buildup. This feature enhances the ease of cleaning and extends the moulds' lifespan.

- User-Friendly Design: The mould frames are engineered for easy and convenient disassembly, allowing for quick maintenance and reduced downtime during production.

QHBake's moulds represent the perfect combination of durability, precision, and customization, meeting the diverse needs of modern confectionery manufacturing.

8.Drying trays

Size:800x400x30mm

Our advantage

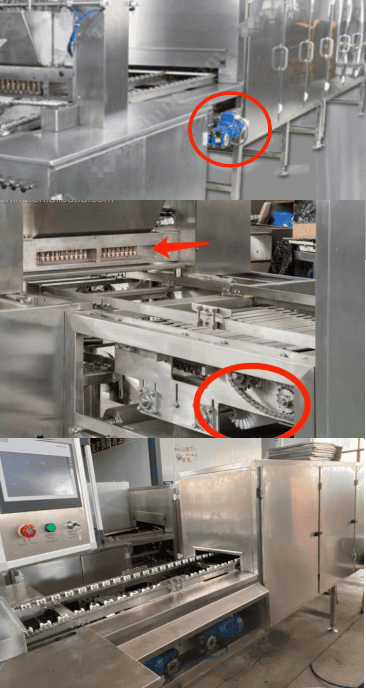

- Enhanced Safety Measures: Each machine is equipped with a robust cover to protect the internal motor, wheels, and chains. This safety feature effectively prevents potential injuries to operators during operation.

- User-Friendly Operation: The machinery is designed for simple operation, allowing workers to handle it with ease. Maintenance procedures are highly flexible, reducing downtime and ensuring efficient upkeep.

- Reinforced Frame Design: Built with a stronger, direct-frame structure, the machine eliminates the need for welded feet. This solid, single-piece construction enhances the machine's stability and extends its service life, making it ideal for demanding production environments.

- Protection & Visual Window: A clear visual window is integrated into the machine, providing operators with an easy way to monitor the production process while maintaining a high level of protection.

- Fully Covered Tunnel Transfer Belt: The tunnel transfer belt runs fully enclosed, preventing it from coming into contact with the floor. This feature helps maintain a clean environment and reduces the risk of contamination.

- Internal Chains and Motors: The chains and motors are securely housed within the tunnel, minimizing exposure to workers and ensuring a safer working environment.

- Stainless Steel Door Handles and Latches: All door handles and latches are made from stainless steel, ensuring durability and reliability. Unlike plastic alternatives, these high-quality components are resistant to wear and corrosion, providing a longer service life.

- Reinforced Frame and Thicker Stainless Steel: The machine frame is constructed from high-strength stainless steel, with a thicker gauge to enhance structural integrity. This robust design contributes to the machine’s longevity and performance, even under heavy-duty use.

Application