A starch mold line is an advanced manufacturing device that employs modified starch as a mold for depositing various types of candies, enhancing the precision and quality of the final product.

The QS300 is a state-of-the-art starch molding machine that offers a high degree of automation and versatility. Its integrated powder loading and pouring system, combined with advanced pouring options and user-friendly controls, makes it an ideal choice for both small-scale and large-scale candy production. By reducing manual labor and enhancing production efficiency, the QS300 helps manufacturers achieve high-quality candy products with ease.

The QS300 can produce a variety of candy types, including:

Dual-Color Candies: Candies with two different colors.

Filled Candies: Candies with a filling or center.

Left-Right Dual-Color Candies: Candies with different colors on the left and right sides.

Tary Size: 400 mm x 800 mm

Material Options: Available in ABS plastic or wooden trays to suit different production requirements and preferences.

Output: 300-600 kg/hr, depending on the type and size of the candies being produced. This flexibility allows the QS300 to accommodate a wide range of candy products, from small to large-scale production runs.

Core Advantages

- Versatility: The starch mold system is not limited by the type of adhesive base or formulation used in candy production.

- Touchscreen Interface: Customers can easily adjust parameters on the touchscreen to produce candies of different weights and sizes. This intuitive interface makes the machine user-friendly and adaptable to various production needs.

- Automated Starch Recycling: The entire starch recycling process is handled by a screw conveyor, which is integrated into the production line. This automation reduces labor requirements and ensures a continuous and efficient production process.

- Efficiency: The QS300 combines powder loading and pouring into a single integrated process, significantly reducing the need for manual labor. This integration streamlines the production workflow, making it more efficient and cost-effective.

- Automation: The machine's design ensures that the starch powder is evenly distributed and accurately poured, minimizing human intervention and enhancing production consistency.

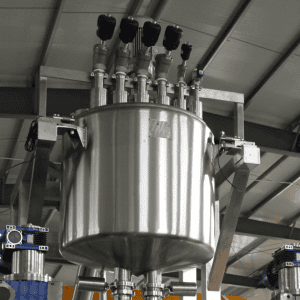

los QHbake kitchen system is designed for efficient, precise, and hygienic production of syrup-based products (e.g., confectionery, jellies, or sauces) using automated temperature-controlled processes. The heating source customer can chose electric or steam or LPG.

Below is a breakdown of the workflow and system specifications:

Cooking Process Overview

Step 1: Melting Syrup/Starch

First Cooker: Heats syrup, sugar water, and starch using steam/jacket heating.

Propósito: Ensures complete dissolution of starch and sugar without burning.

Temperatura: Higher heat (e.g., 85–100°C) to activate starch gelatinization.

Step 2: Hydrating Colloids/Gum Base

Second Cooker: Melts gum bases (pectin, gelatin, agar agar) at lower temperatures (e.g., 50–70°C).

Why Separate? Gums require gentler heating to avoid degradation and ensure proper hydration.

Step 3: Mixing

Second Tank: Combines syrup-starch mixture with hydrated colloids.

Control: Mixing continues until viscosity, pH, or solids content meet preset parameters (ensuring consistency).

Step 4: Storage

Buffer/Storage Tank: Holds finished syrup at controlled temperature until further processing (e.g., molding, filling).

Key System Features

Stainless Steel Construction:Food-contact parts use 316 stainless steel (superior corrosion resistance vs. 304, ideal for acidic/sweet syrups).

Non-contact parts: 304 stainless steel for cost efficiency.

Precision Control

Omron temperature controllers ensure accuracy (±1°C) for starch activation and gum hydration.

Pumps and jacketed pipelines maintain syrup temperature during transport (prevents crystallization or thickening).

Jacketed Insulation Pipes:Double-walled pipes with steam/thermal fluid circulation prevent heat loss and contamination.

Closed System: Minimizes human contact, reducing contamination risks.

Reliable Components

Electrical Appliances: Siemens components ensure durability and safety.

Sealed Pumps: Leak-proof for handling viscous syrups.

This system is ideal for producers prioritizing scalability, precision, and compliance in high-moisture/high-sugar environments.

300 Starch candy depositing machine

The QS300 Starch candy depositing machine with Starch loading function shapes/molds printing on the same machine,starch circulation system,depositing system.

The starch molding system require starch as the primary material for creating molds. Our equipment is designed to evenly distribute the starch, which is delivered from the elevator, onto the molding plate. It features a vibration device and a scraper to ensure that the starch is properly positioned on the plate.

This device can be connected to the depositing machine in line achieve automated linkage.

This machine is made by stainless steel 304.

The die-stamping equipment is designed to automatically detect the plate and its position, allowing it to emboss the pattern onto the correct plate. To prevent the mold from sticking due to starch, we have also installed a vibration device on the equipment.

When a customer needs to change the mold, they can easily switch products by simply replacing the mold plate.

The mold plate measures 400x800mm, and its configuration will lead to varying production capacities based on the type of candy being produced. This mold plate is constructed from stainless steel and coated with Teflon to prevent starch from sticking. Additionally, it features a rough surface to enhance functionality.

The semi-automatic starch mold depositing system has undergone several upgrades, leading to a reduction in the number of components required. The design of the equipment has been modified, allowing it to take up less space compared to traditional starch mold machines, and it is offered at a more competitive price. Additionally, the screw conveyor automatically collects starch into the powder hopper, eliminating the need for manual handling of the starch.

The number of candies poured at one time can be designed to be as large as possible according to the size of the plate. In this way, even if this equipment is mostly used in laboratories, it can also meet the needs of small-scale production.

The depositing piston is made of stainless steel 304. The amount of syrup poured is controlled by servo motor. Each time the type of product is changed, only the setting needs to be adjusted.

There will be induction between the pouring head and the mold plate. It will only move when the mold is sensed, ensuring the safety of the user.

Efficient Drying Process for Jelly Candy Production

The drying room is a critical piece of equipment in the candy production process, designed to effectively remove moisture from jelly candy. By precisely controlling temperature, humidity, and airflow, it ensures the candy achieves the perfect drying state for optimal quality and consistency.

To enhance the drying process, our system incorporates a starch line, where the starch aids in the drying and demolding of candies, ensuring a smooth and efficient production flow.

For added convenience, the drying room is designed to integrate seamlessly with forklifts or cranes, reducing manual labor and streamlining transportation. Additionally, QHhornear offers fully automated drying and conveying systems, tailored to meet your production needs and maximize efficiency.

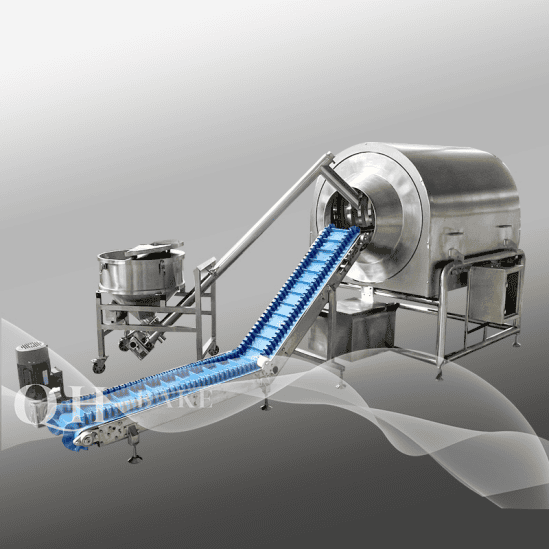

Advanced De-Starching System for Candy Production

After the drying process, separating candy from starch is a critical step that often generates significant waste and dust. To address this, we’ve developed an innovative vacuum negative pressure powder removal system. This cutting-edge design is quieter, more space-efficient, and produces significantly less dust compared to traditional rotary methods.

Our system ensures airtight connections at every stage, while a screw conveyor efficiently transports collected starch powder back to the front for reuse or disposal. The entire de-starching process is fully automated, ensuring precision and reducing manual intervention.

Candies are discharged in a single direction, making it easy for operators to collect them at the exit. Alternatively, candies can be seamlessly transferred to the next production step or packaging via an integrated conveyor belt.

Built for Durability and Hygiene

The equipment is constructed from high-quality stainless steel, with optional sandblasted surfaces to minimize gaps and eliminate sanitary dead corners. To guarantee reliability, we use premium motors and electrical components from globally recognized brands like Siemens.

Enhancing Gummy Candy: Surface Processing Solutions

The surface of gummy candy can be transformed into a variety of stunning effects, from crystal-clear shine to a textured acid sand coating. These finishes not only enhance visual appeal but also offer customers a diverse range of flavors and textures. To achieve these results, our advanced sugar coating and oil/wax coating machines provide the perfect finishing touch for your candy production process.

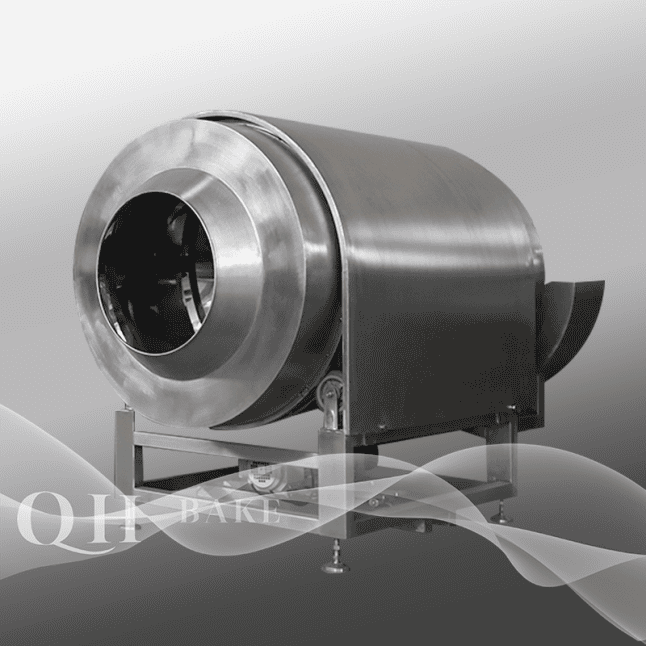

Wax/Oil Coating for a Perfect Finish

Our state-of-the-art oiling and waxing machine evenly sprays edible oil or wax onto the candy surface. The machine features a continuous rotation mechanism to ensure a uniform coating, while an internal screw design automates the transportation of products in and out of the system.

Built with stainless steel 304, our equipment prioritizes hygiene and durability. For added versatility, the machine can be reversed for alternate functions, such as cleaning, making it a multifunctional solution for your production line.

Sugar Sanding for Texture and Flavor

Our sugar sanding process applies fine, uniform sugar particles to the surface of jelly candies, ensuring even adhesion and a consistent finish. This not only enhances the candy’s visual appeal but also elevates the chewing experience by adding a delightful texture and preventing sugar particles from sticking together.