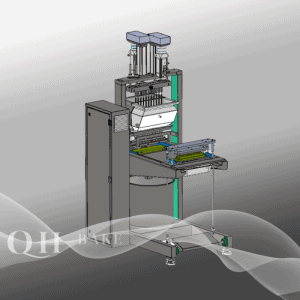

Professional Pectin Gummy Machine | Export Ready

Our Pectin Gummy Machine delivers consistent quality from depositing to cooling. Scalable designs exported to 50+ countries, optimizing your confectionery workflow. Get A Free Quote: Lu@qhbake.comFree Factory Tours

Discover our advanced biscuit and candy production lines via a free guided tour, seeing efficient, high-quality processes in action.

Free Recipes

Get free, expert-tested recipes for biscuits and candies, optimizing flavor, texture, and shelf life for quick, consistent launches.

Teknisk support

Receive free expert support for installation, troubleshooting, and optimization, ensuring smooth operations and maximum ROI.

Innovation

Stay ahead of the competition with the ability to produce unique and functional candies that meet the evolving demands of the market.

Elevate Your Gummy Game: The Pectin Powerhouse Machine

Step into the future of pectin-based confections with our innovative Pectin Gummy Machine, a game-changer for candy exporters chasing clarity and chew. This sleek powerhouse handles everything from pectin dissolution to intricate depositing, churning out vibrant, translucent gummies in endless varieties—think zesty citrus twists or herbal wellness bites—at speeds up to 300kg/hour. Perfect for boutique creators or industrial giants, it locks in flavors with pinpoint temperature precision, yielding treats that bounce back with irresistible snap and stay fresh longer.

Forged in robust 304 stainless steel and ticking all boxes for FDA, EU, and HACCP compliance, safety is non-negotiable. Smart energy tweaks, like adaptive heating coils, trim bills by 25% without skimping on performance, and plug-and-play PLC interfaces let operators swap recipes in seconds, slashing setup hassles.

Shipped to 50+ nations and fine-tuned for your locale’s quirks, from humid tropics to crisp winters, this machine isn’t just gear—it’s your edge in a sweet global race. Pair it with our hands-on training and lightning-fast service, and watch your gummy empire thrive.

Our Production Lines

Advanced Servo Depositing Technology

– Quieter Operation: The screw-type depositor operates with significantly reduced noise levels, creating a more pleasant working environment.

– Enhanced Accuracy: Improved accuracy by 20% ensures consistent product quality and reduces waste.

Versatile Candy Production

– Multiple Styles: The production line can create a wide variety of candy styles, including:

– Center-Filled Candies: Candies with a delicious filling at the center.

– Two-Color Strips: Candies with visually appealing two-color stripes.

– Side-by-Side: Candies with different colors or flavors side by side.

– Layer-by-Layer: Candies with multiple layers of different textures or flavors.

– Multi-Color and Multi-Style Candies: Offering endless possibilities for creative and unique candy designs.

Diverse Candy Types

– Hard Candies: Produce classic hard candies with a variety of flavors and colors.

– Lollipops: Create fun and colorful lollipops for all ages.

– Soft Candies: Manufacture soft, chewy candies with a smooth texture.

– Taffies: Make delicious taffies with a perfect balance of softness and chewiness.

– Functional and Sugar-Free Candies: Utilize different cooking systems to produce candies with functional ingredients or sugar-free options, catering to a wide range of consumer preferences.

Automated Processes

– Automatic Weighing and Cooking of Raw Materials: Ensure precise measurement and consistent cooking of raw materials.

– Automated Mixing of Raw Materials: Achieve uniform mixing for a consistent product quality.

– Automatic Weighting and Mixing of Flavors, Pigments, Acids, and Functional Additives: Enhance the customization of flavors and functional properties, allowing for the production of unique and innovative candy products.

Holistic Support Packages for Production Process Optimization

Our Automatic Starchless Depositing Production Line is the perfect solution for manufacturers seeking to enhance their production capabilities, improve product quality, and expand their product range. Experience the future of candy manufacturing with our advanced and versatile production line.

Precision Pectin Processing

Versatile Molding Capabilities

Hygienic & Compliant Build

Energy-Optimized Performance

User-Friendly Automation

Global Support Network

Testimonials

“Integrating this pancake production line into our facility has revolutionized our output. We’ve seen a 40% increase in efficiency, and the consistency of our pancakes has never been better. The team’s support during installation and training was exceptional.”

“Our investment in this gummy production equipment has paid off tremendously. Not only did it streamline our process, but the quality of our products has also improved, leading to increased customer satisfaction. Highly recommend to any business looking to upgrade their production line.”

“Transitioning to an automated biscuit production system was a big step for our café, but it has allowed us to meet growing demand effortlessly. The consistency and speed of production have improved our service during peak hours. We’re thrilled with the results.”

FAQ

What is the difference between pectin,carrageenan and gelatin?

Pectin: Mainly extracted from plants, especially the peels and pulps of citrus fruits such as oranges and lemons. Apples are also an important source of pectin.The gel formed by pectin has a soft texture, high transparency, and a delicate mouthfeel.

Carrageenan:Mainly derived from red algae, such as Irish moss and deer horn algae.The gel formed by carrageenan has a tough texture, high transparency, and maintains good stability in both cold and hot environments.

Gelatin:A protein extracted from the skin and bones of animals, with common sources including cowhide, pigskin, and fish bones.The gel formed by gelatin has a soft texture, high transparency, and a delicate mouthfeel, but it is sensitive to temperature and will dissolve when heated.

What are the equipment requirements for the different gum bases?

The main differences lie in the cooking process. For pectin and carrageenan, you need equipment for cooking and storage. Compared to pectin and carrageenan, gelatin gum base requires an additional step and equipment for cooling.

What are the temperature requirements for boiling/Kitchen gum base?

Pectin Typically around 105°C to 110°C.

Carrageenan:Generally controlled at 106°C to 108°C.

Gelatin is usually dissolved at a lower temperature range of 70°C to 85°C. Higher temperatures can degrade the gelatin and affect its gelling properties.

What are the benefits/differences of your boiling/kitchen equipment?

1.High-temperature capability 2.Uniform heating and mixing 3.Easy-to-clean surfaces 4.Longer hydration time management

What are the benefits of the soft candy cooker?

Increased Efficiency: It can significantly speed up the cooking process, allowing for higher production volumes in a shorter amount of time.

Bubble-Free Syrup: The cooker helps in eliminating air bubbles from the syrup. This ensures a smoother texture and more consistent appearance in the final gummy candy product.

Consistent Quality: By maintaining precise temperature control and uniform heating, it helps in achieving a consistent texture and quality in every batch of gummy candy.

Ease of Operation: Modern soft candy cookers often come with automated controls and settings, making the process easier and more reliable for both beginners and experienced candy makers.

Hygiene and Cleanliness: Many cookers are designed with stainless steel interiors and easy-to-clean surfaces, which help in maintaining high standards of hygiene and food safety.

What are your payment terms?

Our payment terms are designed to be straightforward and secure, ensuring a smooth transaction process. Here’s a detailed breakdown:

1. Deposit Payment

Amount: 50% of the total order value.

Purpose: This deposit secures your order and initiates the manufacturing process.

Payment Method: Wire transfer, credit card, or other agreed-upon methods.

2. Balance Payment

Amount: The remaining 50% of the total order value.

Timing: The balance is due before shipment.

Purpose: This ensures that the equipment is fully paid for before it is shipped to your facility.

Payment Method: Wire transfer, credit card, or other agreed-upon methods.

3. Payment Methods

Wire Transfer: This is the most common method for international transactions. We will provide you with our bank details for the transfer.

Credit Card: For convenience, we also accept payments via major credit cards.

Other Methods: Depending on your location and preferences, we can explore other payment options

What is the advantage of servo depositing candy line?

Servo-controlled dispensing technology offers significant advantages in various fields,with its high efficiency, stable performance, and precision control, provides strong support for the automation and quality improvement of gummy candy production and other industries.

Can I pack the soft candy directly after it is made?

You generally cannot pack soft candy directly after it is made. Here’s why:

Cooling and Setting: Soft candy needs to cool and set before packaging. This process ensures that the candy has the right texture and consistency. For example, after the candy slurry is poured into molds, it must cool and solidify to take the form of the molds. Packaging it while still warm or soft could lead to deformation or sticking together of the candies.

Drying Process: Some soft candies require a drying phase to remove excess moisture. This is typically done in a drying oven or room where hot air is circulated around the candy. Skipping this step could result in a product that is too sticky or has an inconsistent texture.

Quality Control: Before packaging, candies usually go through a quality control process to ensure there are no defects or inconsistencies in texture, flavor, or appearance. This inspection step is crucial to maintain product quality and consistency.

Packaging Integrity: Packaging materials need to be suitable for soft candies to prevent spoilage or contamination. The packaging process itself involves steps like filling, sealing, and sometimes even cooling the packages to ensure they are properly sealed and maintain the freshness of the candy

What are the requirements of drying work shop size time and temperature?

workshop Size:The size of the drying workshop depends on the production scale. For example, a small workshop may be around 500 square meters.

Drying time:based on the type of candy, its size, and the desired moisture content. Generally, drying times range from 12 to 72 hours

Temperature:usually controlled between 20°C and 45°C. For example, during the initial drying phase, temperatures around 60-65°C are used for gelatin-based candies, while pectin-based candies might require temperatures up to 93-100°C

What is the purpose and difference between the sugar coating machine and the oiling machine?

Coating gummy candies with sugar or oil serves multiple purposes, including achieving a desired appearance (such as a matte or glossy finish) and incorporating functional ingredients

Enhanced Stability: Coatings can help protect the gummy candies from moisture and air, enhancing their shelf life.

Improved Texture: Both sugar and oil coatings can improve the mouthfeel of the candies, making them more enjoyable to eat.

Customization: Coatings allow for customization of flavors and nutritional profiles, catering to different consumer preferences and dietary needs

What is the temperature range of the cooling tunnel?

In the production of gummy candies, the cooling tunnel plays a crucial role in solidifying the candies and ensuring they retain their shape. The temperature range of the cooling tunnel is typically maintained between 5°C and 10°C. This temperature range is optimal for quickly cooling the gummy candies after they are deposited into molds, allowing them to set properly before demolding and packaging.

The cooling tunnel usually operates for a duration of 8 to 12 minutes, during which the gummy candies move continuously through the tunnel. This process ensures that the candies cool evenly and do not stick together, maintaining their quality and appearance.

These temperature and time settings are essential for achieving the desired texture and consistency of gummy candies, ensuring they are ready for the next steps in the production process.

What is the waterproof level of the motor?

In the gummy candy production line, the motors used are typically designed to meet high standards of safety and hygiene. The waterproof level of these motors is crucial to ensure they can operate in a wet or humid environment without malfunctioning. According to industry standards and practices, the motors used in gummy candy production lines are often rated with an IP65 or higher waterproof level. This rating means the motor is protected against dust ingress and low-pressure water jets from any direction, ensuring reliable operation in the production environment.

The IP65 rating is particularly important for food processing equipment to maintain cleanliness and prevent contamination. It allows the motor to withstand regular cleaning and sanitization processes, which are essential for maintaining food safety and hygiene

What certifications do you have?

ISO 9001 Certification: This international standard focuses on quality management systems, ensuring that the production processes are efficient, consistent, and capable of producing high-quality products.

CE Certification: This certification ensures that the equipment complies with European safety, health, and environmental protection standards. It is crucial for manufacturers aiming to sell their products in the European market.

GMP (Good Manufacturing Practices) Certification: GMP outlines the minimum requirements for food manufacturers to produce safe and high-quality products. It covers all aspects of production, including personnel hygiene, manufacturing processes, equipment maintenance, and traceability.

FDA Compliance: For manufacturers targeting the US market, compliance with FDA regulations is essential. This includes adhering to guidelines for cleanliness, hygiene, proper labeling, and ensuring the safety and quality of ingredients and finished products.

ANSI (American National Standards Institute) Standards: ANSI standards provide specific guidelines related to equipment safety, performance, and design. Compliance with these standards helps ensure that the manufacturing equipment meets necessary safety requirements.

HACCP (Hazard Analysis Critical Control Points) Certification: This certification focuses on identifying and controlling potential hazards in the food production process, ensuring food safety and quality.

FSSC 22000 Certification: This certification ensures that the equipment and processes meet global safety and quality requirements, providing assurance that the products are safe for consumers

What is the wiring standard?

Compliance with CE Certification: Ensuring that electrical components meet European safety standards.

Adherence to GMP Standards: Electrical systems must prevent contamination and be easy to clean and maintain.

Meeting FDA Requirements: Ensuring compliance with food manufacturing equipment standards for hygiene and safety.

Compliance with OSHA Standards: Ensuring the safety of electrical systems in the workplace to prevent accidents.

Use of High-Quality Wiring Materials: Selecting food-grade materials that are resistant to moisture, chemicals, and temperature fluctuations.

Regular Maintenance and Inspection: Regularly checking electrical systems to identify and address potential issues, ensuring safe operation

What is the brand of the electrical appliances?(Contact us for others brand)

Siemens: Known for their high-quality PLCs (Programmable Logic Controllers), drives, and sensors.

ABB: Offers a wide range of industrial automation products, including motors, drives, and control systems.

Schneider Electric: Provides comprehensive solutions for electrical distribution and automation, including PLCs, motor starters, and variable frequency drives.

Rockwell Automation: A leading provider of industrial automation and information solutions, including Allen-Bradley PLCs and drives.

Mitsubishi Electric: Offers a variety of automation products, including PLCs, servo motors, and drives.

Omron: Known for their automation and control systems, including PLCs, sensors, and human-machine interfaces (HMIs).

What is the after-sales service? Can you install-and debug at home?

After-Sales Service Content

Video Guidance: We provide video tutorials to help customers understand the installation, operation, and maintenance of the equipment.

Online Support: Technical support is available via phone, email, or video calls.

On-Site Installation and Maintenance: Depending on customer needs, our engineers can visit the customer's factory for equipment installation, debugging, and maintenance.

Free Training: We offer free training for machine installation, operation, and maintenance.

Spare Parts Supply: Some spare parts are provided free of charge, and we offer discounted prices for spare parts to existing customers.

Lifetime After-Sales Service: We provide lifetime after-sales service to ensure customers have no worries during the use of the equipment.

Installation and Debugging Support at Home

Remote Guidance: For home users or small factories, we can provide installation and debugging support through video calls or online guidance.

Detailed Documentation: We provide detailed installation and operation manuals to ensure you can follow the steps to install the equipment correctly.

Technical Support: If you encounter any issues during installation, you can contact our customer service team at any time, and we will provide solutions promptly

What is the material of the conveyor belt?

PVC (Polyvinyl Chloride): This material is commonly used for its durability, ease of cleaning, and resistance to wear and tear. It is also food-grade, ensuring that it meets the necessary hygiene standards for food production

What are the types of gummy bear machines available in the market?

1.Manual Gummy Bear Making Machines:

These are typically more affordable and offer a hands-on approach to gummy bear making. They require the user to heat the gummy mixture manually, pour it into the molds, and monitor the cooling process. Though they lack some of the automatic features, these machines are appreciated for their simplicity and the control they offer to the user.

2.Semi-Automatic Gummy Bear Making Machines:

These machines perform some tasks automatically while others require human assistance. They are suitable for small to medium-scale production and offer a balance between cost and efficiency.

3.Fully Automatic Gummy Bear Making Machines:

These machines are designed for high-volume production and offer complete automation, from mixing and depositing to cooling and packaging. They feature advanced control systems for precise recipe management and high production efficiency.

4.Starch Molding Machines:

These machines use cornstarch as a mold medium. The gummy mixture is deposited into starch molds, and once the candy sets, the starch is removed and recycled. This traditional method is still widely used for its simplicity and effectiveness.

5.Silicone Molding Machines:

Silicone molds are an alternative to starch molds and are becoming increasingly popular due to their reusability and easy maintenance. The gummy mixture is poured into silicone molds and set to cool before extraction.

6.Continuous Depositing Machines:

These machines are a modern approach to gummy bear production. They are fast, efficient, and can produce high volumes of gummies in a short period. The gummy mixture is continuously deposited into molds, set, and then removed from the molds

What should I consider when purchasing a gummy bear machine?

When purchasing a gummy bear machine, consider the following key factors:

Production Capacity:

Choose a machine that matches your production needs (small-scale vs. large-scale).

Automation Level:

Decide between fully automatic (high efficiency) or semi-automatic (more flexible) machines.

Material Quality:

Ensure the machine is made from food-grade materials like stainless steel.

Temperature Control:

Look for precise and adjustable temperature controls.

Ease of Cleaning:

Choose machines that are easy to clean and maintain.

Regulatory Compliance:

Ensure the machine meets food safety standards (e.g., ISO, FDA).

Customization:

Consider machines that allow for shape and flavor customization.

Energy Efficiency:

Opt for energy-efficient models to reduce operational costs.

Vendor Support:

Choose a reputable vendor that offers good after-sales support and warranties.

Cost:

Balance initial cost with long-term savings from durability and efficiency.

What are the production requirements for a commercial gummy bear production line?

Production Capacity: Determine the production scale based on market demand, such as output per hour.

Automation Level: Use automated equipment to improve production efficiency and product quality.

Material Quality: Use food-grade materials, such as stainless steel, to ensure durability and compliance with food safety standards.

Temperature Control: Precisely control the temperature to ensure the quality of the syrup cooking and cooling processes.

Hygiene and Safety: Maintain a clean production environment, regularly disinfect to prevent product contamination.

Regulatory Compliance: Ensure the production line meets relevant food safety regulations and standards.

Customization: Be able to produce gummy bears in different shapes and flavors to meet market demands.

Cooling System: Equip with a cooling tunnel to ensure the gummy bears achieve the right hardness and chewiness.

Packaging Equipment: Have efficient packaging equipment to ensure the products are safely packaged.

Energy Efficiency: Choose energy-efficient equipment to reduce operating costs.

Meeting these requirements can ensure that a commercial gummy bear production line efficiently and safely produces high-quality products

How do I maintain a gummy bear machine?

Regular Cleaning:

Thoroughly clean the machine after each production run to prevent residue buildup and ensure product quality. Use food-safe cleaning agents and avoid harsh chemicals. Pay special attention to molds and filling heads.

Lubrication:

Regularly lubricate moving parts to reduce friction and wear. Use food-grade lubricants that meet international food safety standards. Follow the manufacturer’s guidelines for lubrication frequency and types.

Inspection and Replacement:

Periodically inspect key components like pumps, seals, and drive systems for wear or damage. Replace worn parts promptly to avoid production delays. Keep detailed records of inspections and replacements.

Temperature and Humidity Control:

Maintain the production environment at recommended temperature (20-25°C) and humidity (around 60%) levels to prevent raw materials from absorbing moisture or hardening. Use sensors to monitor and log temperature data.

Employee Training:

Ensure operators are well-trained in machine operation, maintenance, and safety protocols. Training should cover daily inspections, cleaning procedures, and troubleshooting techniques.

Documentation:

Keep a detailed maintenance record system to document all maintenance actions, including cleaning, lubrication, inspections, and parts replacements. Regularly analyze these records to identify potential issues.

Raw Material Quality:

Use high-quality raw materials to improve product quality and reduce equipment strain. Adjust recipes as needed to ensure production efficiency.

By implementing these maintenance practices, you can ensure your gummy bear machine operates efficiently, produces high-quality products, and has a longer lifespan