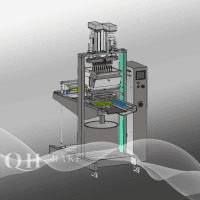

Looking for the perfect candy equipment for your small to medium-sized business? We offer a variety of models and prices to suit different customer needs.

| Model | QH20 | QH20A | QH40 | QH50 | QH50S |

| Depositing Type | Cylinder/Servo | Servo | Cylinder/Servo | Cylinder/Servo | Servo |

| Cavity PCS | ±20 | ±20 | ±20 | ±20 | ±20 |

| Molds sensor | / | / | Yes | Yes | Yes |

| Molds transfer | Add able | Add able | Yes | Yes | Yes |

| Stortingssnelheid | By foot panel | By foot panel | By Sensor | By Sensor | By Sensor |

| Size(cm) | 50x50x150 | 100x80x160 | 150x90x160 | 150x90x160 | 200x100x170 |

| Prijs | $X,XXX | $1X,XXX | $1X,XXX | $1X,XXX | $1X,XXX |

Our semi-automatic candy equipment is versatile and can handle various candy recipes, including soft candies, lollipops, hard candies, toffees, and even cotton candy. With additional auxiliary equipment, you can also produce various types of candies, such as dual-color, filled, and side-by-side candies.

Functies

- Versatile Candy Production: Suitable for producing a wide range of candies, from soft gummies to hard candies and lollipops.

- Space and Cost Efficient: More space-saving and cost-effective than large fully automatic machines, making it ideal for small to medium-sized businesses.

- Customizable Production: Change molds to create various candy types, allowing for flexibility in product variety.

- User-Friendly Operation: Easy to operate with a simple control panel and safety features like an emergency stop button.

- Insulated Dual-Color Hopper: Maintains syrup temperature and allows for dual-color candy production.

Applications

- Small to Medium-Scale Production: Perfect for manufacturers with medium to low volume production requirements.

- R&D and Testing: Ideal for laboratory settings where different candy recipes and types need to be tested.

- Customized Solutions: Contact our sales team for tailored solutions to meet your specific production needs.

Technical Specifications

- Dimensions: Compact design suitable for small production spaces.

- Production Capacity: Varies depending on the model, suitable for different business scales.

- Power Supply: Standard electrical requirements for easy installation.

- Material: High-quality food-grade materials ensuring safety and durability.

Why Choose Us?

Our commitment to quality and customer satisfaction ensures that you receive equipment tailored to your needs. With our QH50 Semi-Automatic Candy Depositing Machine, you can enhance your production efficiency and product diversity without the high costs and space requirements of fully automatic systems.

Contact us today to learn more about how our candy depositing machines can elevate your confectionery business!

|

QH20

Cylinder deposit Foot panel control |

|

QH20A

Labotry one Servo&touch screen |

|

QH40

Semi auto Cylinder push and deposit |

|

QH50

Semi auto Auto Molds transfer and deposit |

|

QH50S

Automated Servo Molds transfer and deposit |

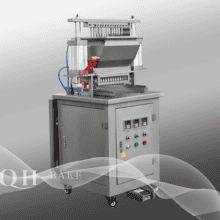

# Small Vacuum Cooker

Our small vacuum cooker is a specialized laboratory - production equipment we've developed for small - scale candy making. It can be fitted with homogenizers and stirrers to meet diverse experimental and production requirements. The syrup produced via vacuum neg - pressure cooking has low moisture, a clear appearance, and fewer bubbles, crucial for high - quality candy.

Choose our small vacuum cooker to enhance your syrup preparation with precision and efficiency. Perfect for labs and small businesses seeking to improve product quality and production flexibility.

What are the benefits of vacuum cooking for cooking syrup?

Vacuum cooking offers several significant advantages for syrup preparation in candy making:

Low-Temperature Dehydration: Vacuum cooking reduces the boiling point of sugar solutions, allowing for dehydration at lower temperatures. This helps maintain the activity of heat-sensitive components in the syrup and prevents the destruction of ingredients such as foaming agents in milk candies.

Enhanced Product Quality: The process ensures more uniform heating and evaporation, resulting in syrup with better color uniformity and higher transparency. This is particularly important for candies where visual appeal is crucial.

Efficiency and Speed: Vacuum cooking systems, such as vacuum film evaporators, enhance heat exchange efficiency and shorten the cooking cycle. This leads to higher production rates and improved labor productivity.

Energy Savings: By lowering the temperature required for syrup concentration, vacuum cooking reduces energy consumption compared to traditional atmospheric cooking methods

Reduced Risk of Caramelization: The lower cooking temperatures minimize the risk of caramelization and burning, ensuring a smoother final product and reducing waste due to over-cooking.

Versatility: Vacuum cooking equipment can handle various types of syrups and candies, including hard candies, soft candies, lollipops, and toffees, making it a flexible solution for different production needs.

Advanced Control Systems: Modern vacuum cooking machines often feature PLC control systems with touchscreens for easy operation and precise parameter adjustment, improving production consistency and reducing the likelihood of human error.

Safety and Reliability: These systems typically incorporate safety interlocks and self-diagnostic capabilities, ensuring safe operation and reducing downtime for maintenance.

Scalability: Vacuum cooking equipment is available in various sizes and configurations, making it suitable for both small-scale production and larger manufacturing operations.

By leveraging these benefits, vacuum cooking technology provides candy manufacturers with a powerful tool to enhance product quality, production efficiency, and operational flexibility.

All types of molds can be used on this machine:

Metal molds

Metal Molds with Aluminum Base and Teflon Coating: Key Insights

1.Material Benefits:

-Aluminum Base:

-Lightweight & Durable: Reduces machinery strain in automated systems, lowering operational costs.

-High Thermal Conductivity: Enables rapid heating/cooling, boosting production efficiency and cycle times.

2.Teflon (PTFE) Coating:

-Non-Stick Properties: Ensures easy release of molded parts, minimizing defects and downtime.

-Applications: Ideal for food, plastics, pharmaceuticals, and other industries requiring contamination-free processes.

-Durability: Applied via bonding/spraying; withstands moderate stress but may degrade under abrasive use or extreme temperatures (PTFE max: ~260°C/500°F).

3.Automation Compatibility:

- Designed for seamless integration with robotic systems (precise dimensions, standardized mounts).

- Lightweight aluminum reduces handling costs, while non-stick surfaces eliminate the need for release agents, streamlining workflows.

4.Maintenance & Longevity:

- Avoid abrasive tools to protect the coating.

- Recoating possible in some cases, though costs vary. Thermal expansion compatibility ensures coating adhesion during temperature cycles.

5.Cost Considerations:

- Higher upfront cost vs. uncoated molds, but offsets via reduced downtime, longer lifespan, and lower cleaning needs.

6.Limitations:

- Not suitable for ultra-high-temperature processes (e.g.,某些高温塑料成型).

- Coating wear in abrasive applications may require frequent maintenance.

7.Alternatives:

- Steel molds with ceramic coatings for high-temperature/abrasive use, albeit heavier and costlier.

Conclusion: Aluminum-Teflon molds excel in automated, high-efficiency environments where non-stick performance and thermal management are critical. Proper use and maintenance ensure cost-effective, long-term operation across diverse industries.

Soft Silicone molds

Soft Silicone Molds with Steel Reinforcement: Key Insights

1.Material Benefits:

-Silicone Body:

-Flexibility & Elasticity: Ideal for intricate shapes and soft products (e.g., confectionery, wax, soap, soft plastics) that require gentle demolding.

-Inherent Non-Stick Properties: Reduces the need for external release agents, though less durable than Teflon coatings.

-Heat Resistance: Withstands moderate temperatures (typically up to 200–250°C/392–482°F), suitable for baking, low-melt plastics, or resin casting.

2.Steel Reinforcement:

-Structural Stability: Embedded steel bars or frames counteract silicone’s natural flexibility, preventing deformation during automated handling or high-pressure casting.

-Dimensional Precision: Ensures consistency in product geometry, even with complex designs.

-Longevity: Steel supports extend the mold’s lifespan by reducing wear from repeated use.

3.Automation Compatibility:

-Robust Mounting: Steel components enable secure attachment to robotic arms or conveyor systems.

-Alignment Accuracy: Steel ensures precise positioning in automated workflows, critical for high-volume production.

-Reduced Downtime: Non-stick silicone minimizes part adhesion, streamlining continuous demolding cycles.

4.Applications:

-Delicate Products: Perfect for food (chocolates, gummies), cosmetics (soap, candles), medical devices (soft polymer components), and arts/crafts.

-Complex Geometries: Captures fine details (e.g., textures, undercuts) that rigid molds cannot replicate.

5.Maintenance & Limitations:

-Cleaning: Gentle washing required; avoid abrasive tools to prevent tearing.

-Durability: Silicone degrades faster than metal under mechanical stress or high temperatures; steel reinforcement mitigates but does not eliminate wear.

-Thermal Constraints: Lower thermal conductivity than aluminum molds may slow heating/cooling cycles.

6.Cost Considerations:

- Lower upfront cost than metal molds, but shorter lifespan in high-stress environments.

- Cost-effective for small-batch artisanal production or highly detailed designs.

7.Alternatives:

-Hybrid Molds: Combine silicone cavities with aluminum/steel frames for enhanced thermal performance.

-High-Temp Silicones: Specialty grades (e.g., platinum-cure) for applications requiring >250°C resistance, at higher cost.

Comparison with Aluminum-Teflon Molds:

-Advantages: Superior flexibility, intricate detail capture, and lower cost for niche applications.

-Drawbacks: Slower thermal response, less durable in abrasive/high-temp settings.

Conclusion: Silicone molds with steel reinforcement are optimal for automated production of soft, detailed products where flexibility and gentle demolding are critical. They bridge the gap between rigid industrial molds and artisanal tooling, offering versatility in food, crafts, and soft-material manufacturing.

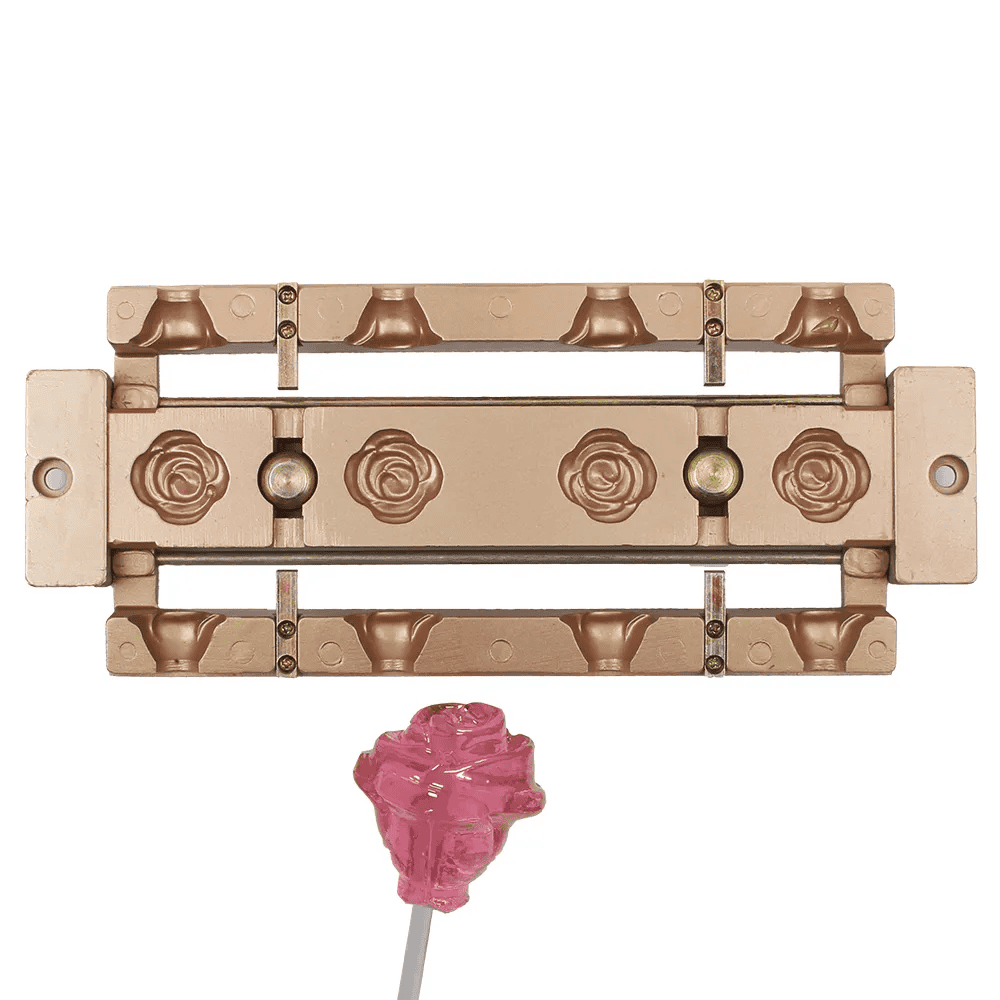

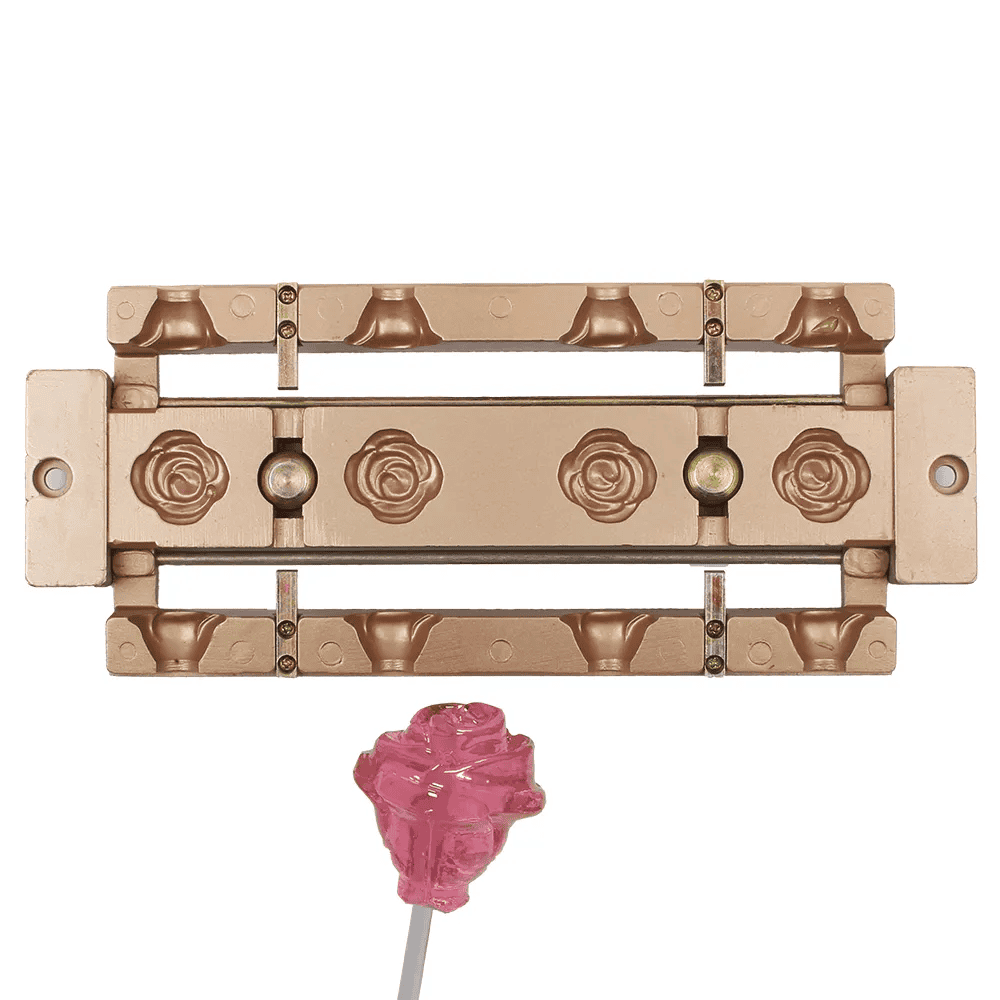

3D /Lollipop molds

3D Aluminum Molds with Teflon Coating for Candy Production (e.g., Lollipops, LEGO-Shaped Gummies):

1. Core Advantages

Aluminum Base Properties:

Lightweight & High Precision: Ideal for intricate 3D structures (e.g., LEGO bricks, detailed textures); CNC machining ensures accurate detail reproduction.

Rapid Thermal Conductivity: Shortens candy cooling/solidification time, boosting production efficiency (critical for fast demolding of soft candies and lollipops).

Teflon (PTFE) Coating

Non-Stick Surface: Prevents syrup residue, ensures glossy finishes, and reduces manual cleaning costs.

Food Safety Compliance: FDA-approved, eliminates chemical migration risks for direct food contact.

Design Considerations

Mold Structure Optimization:

Parting Line Design: Precision parting lines for 3D shapes (e.g., lollipop stick slots, LEGO studs) to avoid demolding damage.

Vent Channels: Prevent air bubbles, ensuring flawless candies (especially for transparent or high-clarity products).

Uniform Coverage: Spraying or electrostatic deposition ensures Teflon coats hard-to-reach areas (e.g., deep cavities, fine protrusions).

High-Speed Demolding:

Compatible with pneumatic/hydraulic ejection systems for precise release of delicate 3D candies (prevents soft gummy deformation).

Lightweight aluminum reduces robotic arm load, ideal for continuous production lines.

Temperature Control Integration:

Built-in heating/cooling channels enable rapid temperature adjustments for diverse candy formulations (e.g., hard candies require high heat, soft gummies need quick cooling).

Applications

Typical Products:

3D Gummies: LEGO-shaped candies, animal-shaped soft candies (reliant on high-precision mold textures).

Lolly: Integrated molding of custom handles + spherical candy bodies, requiring seamless parting lines.

Functional Candies: Embedded structures (e.g., layered fillings, interlocking designs).

Industry Expansion:

Pharmaceutical gummies (vitamin supplements), 3D-printed food prototyping.

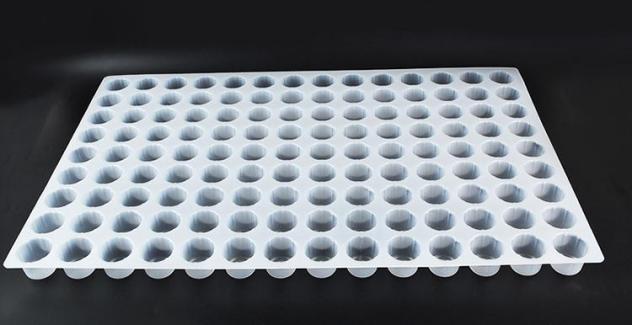

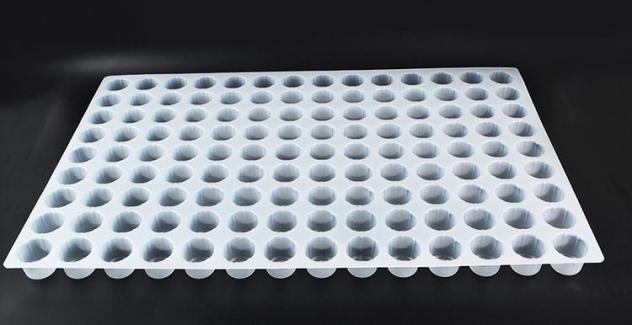

Plastic molds

# Blister Mold: Cost-Effective Solution for Diverse Candy Shapes

The blister mold is a relatively low-cost mold, suitable for customers who have a variety of products in different shapes and need to change molds frequently. It cannot withstand high temperatures and is usually used for products such as marshmallows and chocolates.

Cost-Effective Solution

The blister mold is designed to offer a cost-effective solution for manufacturers who require flexibility in their production processes. Unlike high-cost, specialized molds that are only economical for large-scale production runs, blister molds can be easily replaced and are ideal for small to medium production batches. This makes them particularly suitable for businesses that produce a diverse range of candy products, each with unique shapes and sizes, without the need for significant investment in custom molds.

Flexibility for Frequent Changes

One of the key advantages of the blister mold is its flexibility. Customers who frequently change their product shapes and sizes will benefit from the ease of switching molds. This flexibility is crucial for businesses that need to adapt quickly to market demands, seasonal variations, or special orders. The ability to rapidly change molds minimizes downtime between production runs, allowing for more efficient use of production time and resources.

Limited Temperature Resistance

It's important to note that blister molds are not designed to withstand high temperatures. They are typically used in applications where the processing temperatures are relatively low. This makes them ideal for products like marshmallows and chocolates, which do not require high-temperature processing. For manufacturers producing these types of candies, the blister mold provides an excellent balance between cost, flexibility, and functionality.

Ideal for Specific Products

The blister mold is particularly well-suited for products such as marshmallows and chocolates. These products benefit from the mold's ability to create precise shapes and details without the need for high-temperature tolerance. The relatively low cost of the mold also aligns well with the production volumes typically associated with these products, making it a practical choice for many manufacturers in this space.

Applications

-Marshmallows: The blister mold can create various shapes and sizes of marshmallows, from classic cylindrical shapes to more intricate designs.

-Chocolates: Ideal for molding chocolates with detailed shapes and patterns, enhancing the visual appeal of the final product.

-Other Confectionery: Suitable for any candy product that requires low-temperature processing and frequent mold changes.

Technical Specifications

-Material: Typically made from materials that can withstand the temperatures required for marshmallows and chocolates.

-Durability: Designed for frequent use and easy replacement, ensuring long-term performance without significant wear and tear.

-Compatibility: Works well with standard candy production equipment, allowing for seamless integration into existing production lines.

Choose our blister mold to enhance your candy production process with a cost-effective, flexible solution that meets the needs of your diverse product lineup. Perfect for businesses looking to maintain quality while adapting quickly to changing market demands.