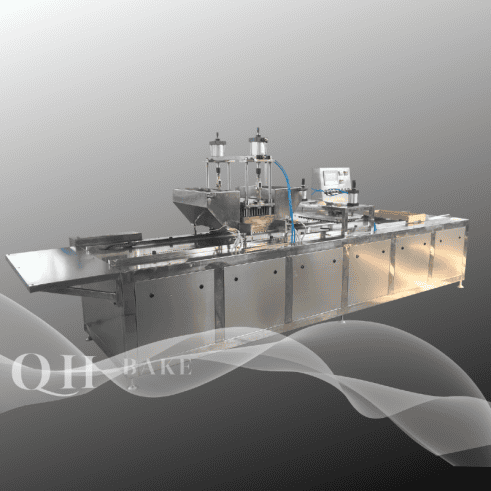

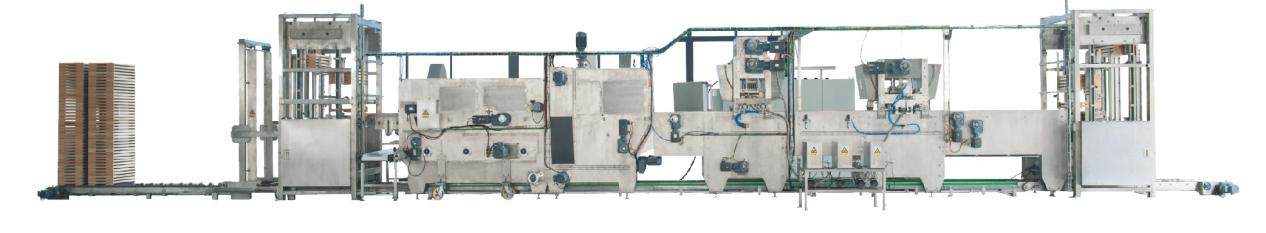

A starch mold line is an advanced manufacturing device that employs modified starch as a mold for depositing various types of candies, enhancing the precision and quality of the final product.

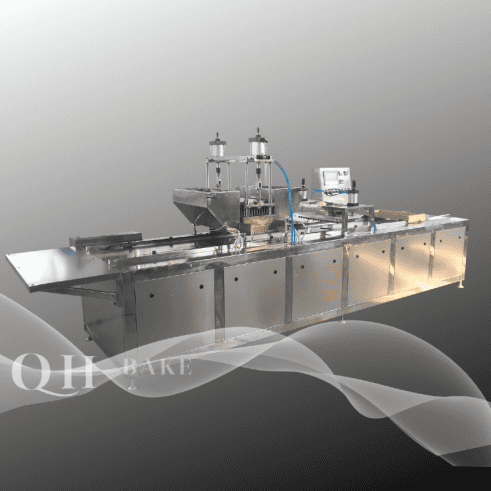

The system comprises several integrated components, including a fully automatic cooking system for optimal starch preparation, a pressure molding line that shapes the candy accurately, and a sophisticated starch processing system that ensures uniformity in mold quality.

This setup also features automatic upper and unload plate equipment for seamless handling of the candy molds by manual, a starch collection and recovery system designed to minimize waste, and a fully automated packaging line that streamlines the final stages of production.

One of the key advantages of the starch mold system is its versatility; it is not constrained by the type of adhesive base or formulation used in candy production. The innovative 360° temperature control feature significantly improves the accuracy of the molding process, reduces defects associated with tail materials, and shortens drying times, ultimately leading to enhanced production efficiency.

Our company’s automated equipment is designed to effectively reduce dust generation during the production process while incorporating a dedicated starch drying function, which together facilitate a fully automated production environment. The starch mold line boasts an impressive capacity ranging from 1000 to 2500 kg/h and operates at speeds between 15 and 32 trays per minute, making it suitable for high-volume production.

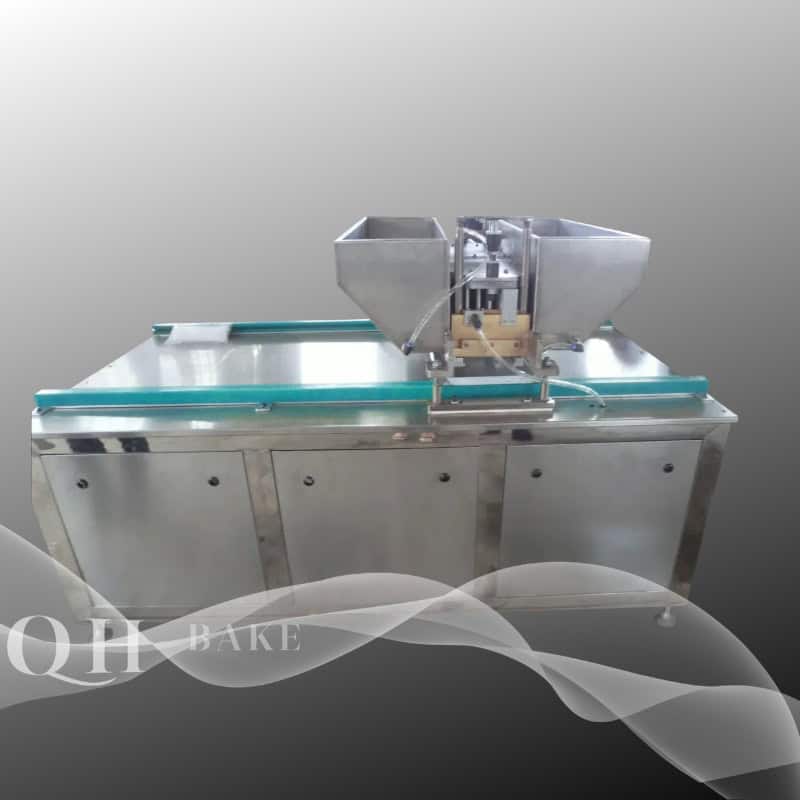

For operations requiring more flexibility, we also provide a semi-automatic starch mold machine that allows for manual intervention when necessary, ensuring adaptability to various production needs.

|

QS50: Click to Check Details

Mini Laboratory Capacity:50kg/h Trays size:400x400mm |

|

QS150: Click to Check Details

Semi automatic Capacity:150kg/h Trays size:400x600mm |

|

QS300: Click to Check Details

Capacity:300-600kg/h Trays size:400x800mm |

|

QS720: Click to Check Details

720pcs/time Capacity:600-1000kg/h Fully automatic Trays size:400x800mm |

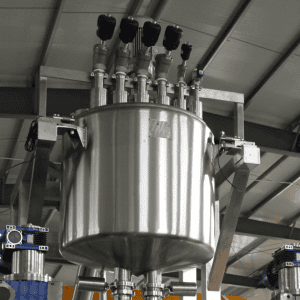

Automatic kitchen system

How Automatic Weighing and Boiling Systems Transform Cooking Habits ?

Understanding the Technology of Automatic Weighing and Food Safety?

How Automatic Systems Ensure Perfect Measurements and Cooking Times?

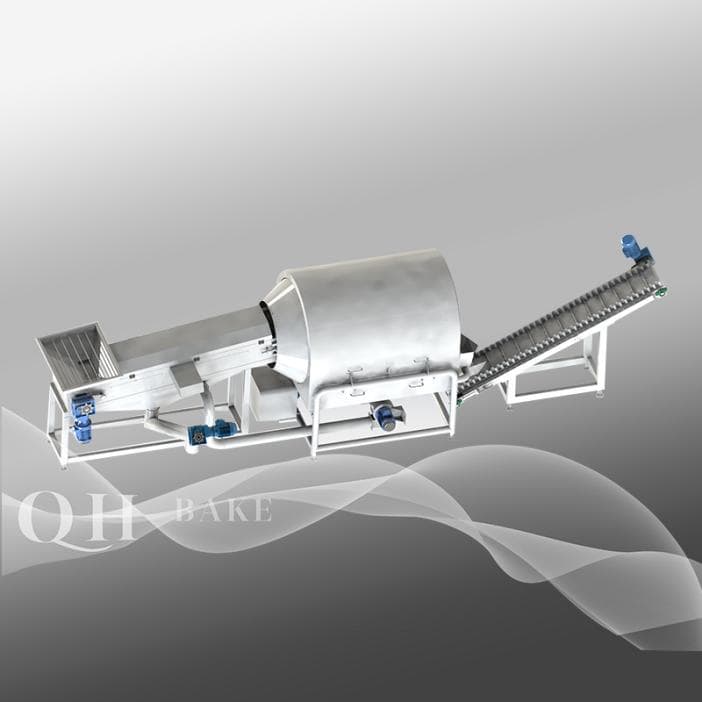

De-Starch system

Once the candy has dried, it is important to separate it from the starch.

How to ensure that dust is reduced during the de-powdering process of the equipment?

How to smoothly separate the starch of candy in the Starch Mogul line?

Sugar sanding system

How to wrap sour sand smoothly on gummy candy?

The machine contains three internal layers, filled with sour sand or white sugar. These materials are continuously rotated by the machine's roller structure and fall through a sieve onto the candies being transported inside.The candy keeps rotating along with the drum.

How to ensure that the excess white sugar will not fall out with the candy during the sanding process?

The screw of the sugar layer spirals inward, while the candy spirals outward, allowing for complete reuse without removal.

Oil/wax coating system

How do you make the surface of gummy candy shiny?

The surface of candy can exhibit various effects; some may appear crystal clear and shiny, while others may have a layer of acid sand coating them. The shiny surface usually form the last step to coating the eatable wax or oil on the coating drum.

What kind of substance is coated on the surface of the gummies? Is it edible?

Yes,usually by carnauba wax is mixed with a neutral oil like grapeseed or sunflower

How does this machine works?

The formed candies are placed in the coating drum. The machine is equipped with an independent oil spraying system. The soft candies are coated with wax and oil while spirally rotating on the wall of the tube.

Drying Plate

Whats the difference between two material trays?

In candy production, drying plates are essential for holding and drying confectionery products during various stages of processing. The choice between wooden and ABS (Acrylonitrile Butadiene Styrene) drying plates can significantly impact the efficiency, hygiene, and durability of the production process. Here’s a comparison of both materials:

1. Material Composition

- Wooden Drying Plates: Made from natural wood, typically hardwood varieties.

- ABS Drying Plates: Manufactured from ABS plastic, a durable and food-safe synthetic material.

2. Hygiene & Food Safety

- Wooden Plates: Porous surface absorbs moisture, which can lead to bacterial growth and contamination risks. Requires frequent cleaning and drying.

- ABS Plates: Non-porous and resistant to moisture, making them more hygienic and easier to clean. Suitable for food-grade environments.

3. Durability & Lifespan

- Wooden Plates: Prone to cracking, warping, and absorbing flavors over time. Lifespan is shorter, especially in humid conditions.

- ABS Plates: Highly durable, resistant to cracking and warping, and maintains structural integrity for a longer period.

4. Maintenance & Cleaning

- Wooden Plates: Require thorough cleaning and drying after each use to prevent mold and contamination. Cannot be cleaned with harsh chemicals.

- ABS Plates: Easy to wash with standard food-safe detergents and can be sanitized efficiently. Resistant to mold and bacteria.

5. Weight & Handling

- Wooden Plates: Heavier, which may make handling more difficult and increase labor costs.

- ABS Plates: Lightweight and easier to move, reducing physical strain on workers.

6. Cost & Investment

- Wooden Plates: Generally lower initial cost but may require frequent replacements.

- ABS Plates: Higher initial cost but longer lifespan, reducing long-term replacement expenses.

7. Environmental Impact

- Wooden Plates: More environmentally friendly since wood is biodegradable and renewable.

- ABS Plates: Made from plastic, which is not biodegradable but can be recycled.

Conclusie

For traditional candy production, wooden drying plates have been widely used, but ABS drying plates are becoming the preferred choice due to their superior hygiene, durability, and ease of maintenance. The selection depends on production scale, regulatory compliance, and long-term cost considerations.

Wooden:

ABS: