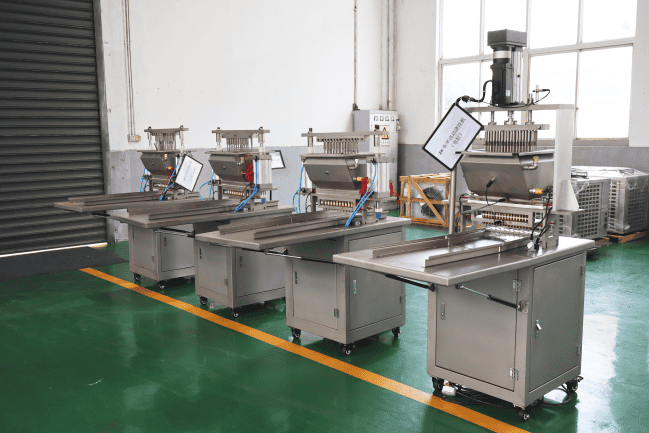

Engineered for boutique candy ateliers, R&D laboratories, artisanal dessert studios and chain store operations, delivering end-to-end capabilities from prototyping to limited batch production.

Redefining Confectionery Innovation

Key Advantages:

▶ Compact Industrial Design

0.65m² footprint with modular assembly system enables rapid deployment. Ergonomic foot-pedal activation paired with expandable folding workstation achieves smart spatial conversion, requiring no specialized technical expertise for installation.

▶ Pharmaceutical-Grade Manufacturing

Full-process components feature medical 304 stainless steel with triple mirror-polishing (Ra≤0.4μm surface roughness). FDA/CE certified quick-disassembly modules ensure thorough sanitization compliance.

▶ Flexible Production System

Equipped with patented Quick-Change Mold Technology (QCMT 3.0) compatible with 95% industry-standard molds. Intelligent metering pump delivers 0.1ml precision dosing for hard candies, gummies, filled confections and more. Visual interface stores 20 preset formulation profiles.

▶ Sustainable Value Engineering

Military-grade cast frame with Swiss ABB drive systems passes 200,000-cycle endurance testing. 40% energy reduction and 3x extended maintenance intervals deliver 60% lower TCO versus conventional equipment.

| Modèle | QH20 | QH20A | QH40 | QH50 | QH50S |

| Depositing Type | Cylinder/Servo | Servo | Cylinder/Servo | Cylinder/Servo | Servo |

| Cavity PCS | ±20 | ±20 | ±20 | ±20 | ±20 |

| Molds sensor | / | / | Yes | Yes | Yes |

| Molds transfer | Add able | Add able | Yes | Yes | Yes |

| Vitesse de dépôt | By foot panel | By foot panel | By Sensor | By Sensor | By Sensor |

| Size(cm) | 50x50x150 | 100x80x160 | 150x90x160 | 150x90x160 | 200x100x170 |

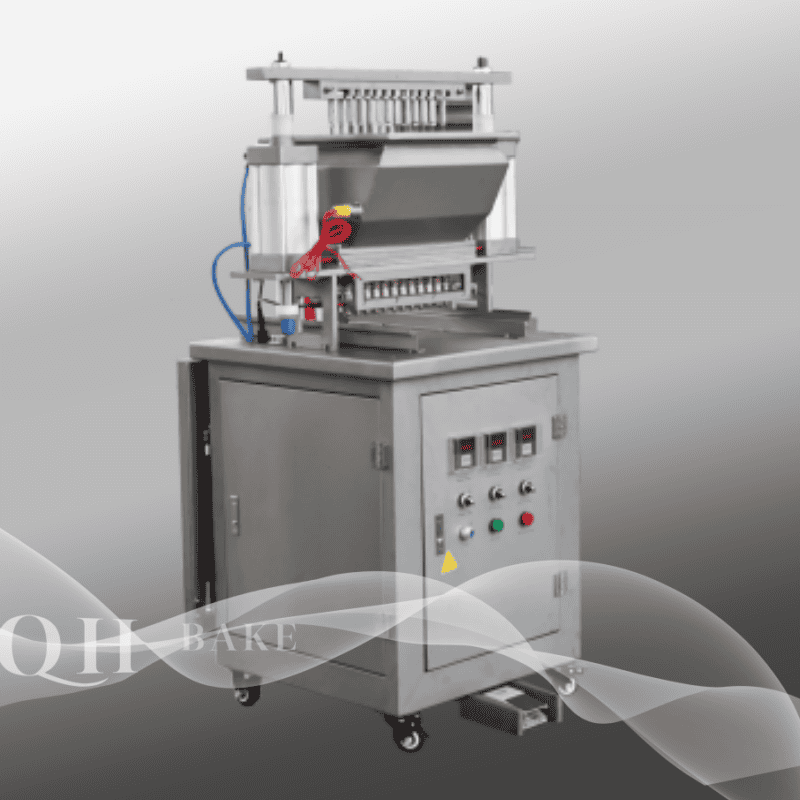

QH-20 Dual-Mode Intelligent Candy Manufacturing System

Where Culinary Art Meets Industrial Precision

Strategic Value Proposition

Engineered for food innovation labs, chain store commissaries, artisanal confectioners and R&D institutions, delivering:

✓ Laboratory-grade accuracy + Production-level throughput

✓ Artistic freedom + Industrial quality control

✓  Compact footprint + Scalable productivity

Compact footprint + Scalable productivity

Engineering Breakthroughs

Dual-Drive Injection System

Pneumatic Mode (Economy)

Servo Mode (Precision)

Dual control with foot pedal/manual pulse injection

Guaranteed 20pcs/cycle standardized output

Standard: Single-color filling (15s/batch)

Advanced: Dual-color parallel/alternate injection with marbling/gradient effects

Triple-certified (ISO9001/ISO22000/FDA)

Energy consumption ≤1.2kW·h/1,000pcs in servo mode