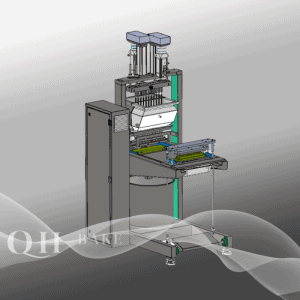

QG40 Halvautomatisk slikafsætningsmaskine: Cylinder/Servo; Kavitets-PCS: ±20; 150x90x160 Størrelse (cm)

Kontakt os

We offer a range of semi-automatic candy pouring machines, each designed to meet specific production needs. Our Model 40 semi-automatic candy machine, equipped with a cylinder mold-pushing mechanism, stands out as a significant upgrade from laboratory-scale equipment.

With its high efficiency, stability, and flexibility, it plays a crucial role in the candy production sector, providing a reliable production solution for candy manufacturers and professionals.

| Model | QH20 | QH20A | QH40 | QH50 | QH50S |

| Depositing Type | Cylinder/Servo | Servo | Cylinder/Servo | Cylinder/Servo | Servo |

| Cavity PCS | ±20 | ±20 | ±20 | ±20 | ±20 |

| Molds sensor | / | / | Yes | Yes | Yes |

| Molds transfer | Add able | Add able | Yes | Yes | Yes |

| Deponeringshastighed | By foot panel | By foot panel | By Sensor | By Sensor | By Sensor |

| Size(cm) | 50x50x150 | 100x80x160 | 150x90x160 | 150x90x160 | 200x100x170 |

1. Increased Production Capacity:

- The Model 40 offers higher output compared to laboratory-scale devices, making it suitable for small to medium-scale production runs.

- Its enhanced capacity ensures that manufacturers can meet market demands more effectively.

2. Efficiency and Stability:

- The machine's design ensures consistent performance, reducing downtime and increasing overall production efficiency.

- Its stable operation guarantees uniform product quality, minimizing defects and waste.

3. Flexibility and Versatility:

- By simply changing molds and adjusting process parameters, the Model 40 can produce a wide variety of candy types and sizes, including hard candies, soft candies, chocolate candies, filled candies, and more.

- Whether producing traditional round candies or creatively shaped novelty candies, this machine can adapt to meet diverse and personalized market demands.

4. Reliable Production:

- The inclusion of a cylinder mold-pushing mechanism ensures smooth and reliable demolding, reducing the risk of product damage.

- This feature enhances the machine's reliability, making it a dependable choice for consistent production.

Semi-Automatic Candy Machine: Features and Benefits

1. Cylinder Mold-Pushing Mechanism:

- Pneumatic cylinders, as mature pneumatic actuators, feature simple structures, stable performance, and long service life.

- Under normal use and maintenance, the cylinder-driven candy machine operates stably for extended periods, reducing equipment failure and downtime. This lowers repair costs and minimizes disruptions to production.

2. Intuitive Touchscreen Control:

- The machine is equipped with an intuitive touchscreen interface, making operation simple and user-friendly.

- Operators can easily set and save parameters directly on the touchscreen, enhancing operational convenience and reducing the likelihood of human error.

3. Low Labor Demand:

- Designed for ease of use, our equipment can be operated by a single person. This reduces labor costs and increases operational flexibility, making it ideal for small-scale production and R&D environments.

4. Equipped with Auxiliary Wheels:

- Wheels allow the machine to be easily moved between different locations without the need for significant manpower. Whether adjusting the machine's position within a factory workshop or moving it between offices, warehouses, or other locations, the process becomes much more convenient.

5. Improved Cleaning Efficiency:

- The simple design allows cleaning personnel to access all parts of the machine more easily. Whether using a wet cloth, water gun, or other cleaning tools, the cleaning process is more comprehensive and faster.

6. Built-in Oil Spraying Function:

- The machine features an oil spraying function with controllable oil output and nozzle direction, enabling the production of high-quality candies.

7. Temperature Probe Included:

- The temperature probe accurately measures the actual temperature of candy ingredients during heating and cooling processes. For example, when boiling hard candy syrup, the temperature probe precisely measures the syrup temperature, providing accurate data for operators.

Why Choose Our Model 40 Semi-Automatic Candy Machine?

- High Output: Increased production capacity compared to laboratory equipment, suitable for small to medium-scale production.

- Consistent Quality: Stable operation ensures uniform product quality, reducing defects and waste.

- Adaptability: Ability to produce a wide range of candy types and shapes by changing molds and adjusting parameters.

- Ease of Use: User-friendly design and reliable performance make it an ideal choice for both experienced manufacturers and newcomers to the industry.

- High Efficiency: Increased production capacity compared to laboratory equipment, suitable for small to medium-scale production.

- User-Friendly: Intuitive controls and simple operation make it accessible for both experienced manufacturers and newcomers.

- Versatility: Ability to produce a wide range of candy types and shapes by changing molds and adjusting parameters.

- Cost-Effective: Reduces labor costs and minimizes downtime, offering a reliable solution for candy production.

Our Model 40 semi-automatic candy machine is designed to provide manufacturers with a versatile and reliable production solution. Whether you are looking to expand your product line or improve production efficiency, this machine is a valuable addition to your production facility. Experience the benefits of high efficiency, stability, and flexibility with our Model 40 semi-automatic candy machine.