The QS50 is a Mini Laboratory machine,Suitable for customers who need laboratories or small-scale production.The main machine requires only 1-2 meters of space, and the entire equipment set can be customized to fit the customer's workshop size, minimizing the footprint.

In addition to making jelly candies, this equipment can also produce various starch-based products, including real liquid chocolate cores, relatively viscous candy cores like Skittles, and starch-based wafer sugar balls such as Mylikes.

- Capacity:20-50kg/h

- Trays size: 400x400mm

- Types:Single color only/ two color only

Starch mold production process

Madlavningsproces

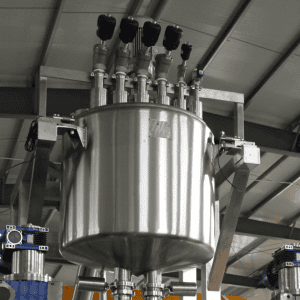

Utilize steam or jacket heating to boil and melt syrups, starches, and colloids. The heated materials are then automatically transported to the next stage through pumps and heating pipelines.

- Step 1 Melting syrup sugar water and starch in first cooker.

- Step 2 Melting gum base for example pectin gelatin agar agar ina lower temperate at another cooker.

- Step 3 Mix the finished product into the second tank until the set data.

- Step 4 Transfer the ready syrup into the buff/storage tank.

QHbake kitchen system uses all stainless steel and the contact food parts can choose 316 instead of 304.

All electrical appliances are from Siemens and other well-known brands, and the temperature control is from Omron.

The pipeline and pump are sealed with jacketed insulation pipes to keep the syrup at the set temperature and transport it to the next link.

Starch loading machine

The starch molding equipment requires starch as the primary material for creating molds. Our equipment is designed to evenly distribute the starch, which is delivered from the elevator, onto the molding plate. It features a vibration device and a scraper to ensure that the starch is properly positioned on the plate.

This device can be connected to the depositing machine in line achieve automated linkage.

This machine is made by stainless steel 304.

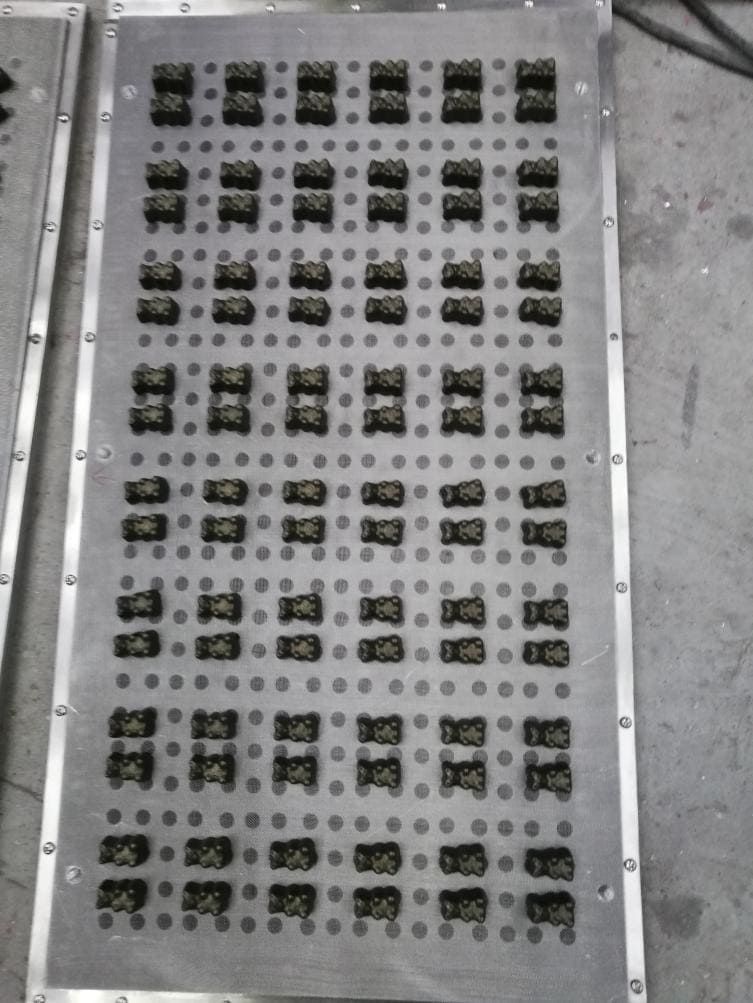

shapes/molds printing on the starch mold

The die-stamping equipment is designed to automatically detect the plate and its position, allowing it to emboss the pattern onto the correct plate. To prevent the mold from sticking due to starch, we have also installed a vibration device on the equipment.

When a customer needs to change the mold, they can easily switch products by simply replacing the mold plate.

The mold plate measures 50x50 centimeters, and its configuration will lead to varying production capacities based on the type of candy being produced. This mold plate is constructed from stainless steel and coated with Teflon to prevent starch from sticking. Additionally, it features a rough surface to enhance functionality.

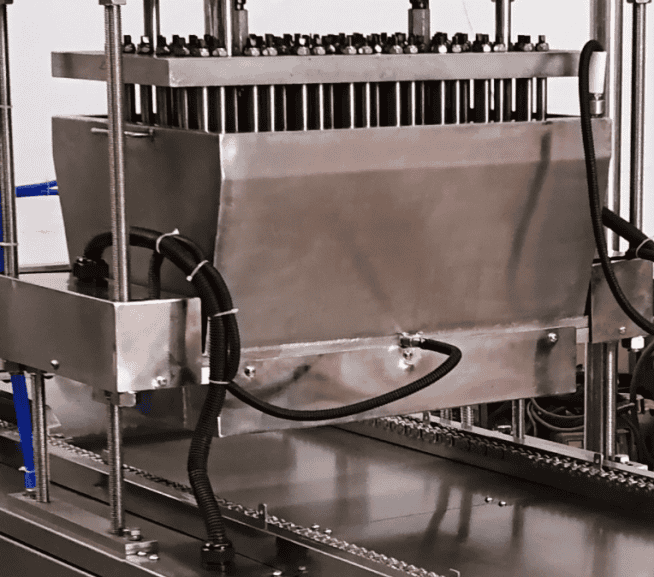

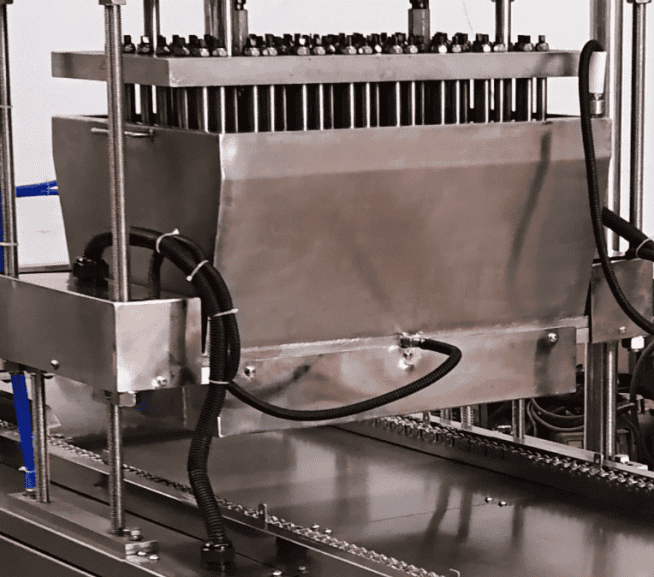

4.Depositing/pouring syrup

The semi-automatic starch mold depositing pouring equipment has undergone several upgrades, leading to a reduction in the number of components required. The design of the equipment has been modified, allowing it to take up less space compared to traditional starch mold machines, and it is offered at a more competitive price. Additionally, the screw conveyor automatically collects starch into the powder hopper, eliminating the need for manual handling of the starch.

The number of candies poured at one time can be designed to be as large as possible according to the size of the plate. In this way, even if this equipment is mostly used in laboratories, it can also meet the needs of small-scale production.

The common pouring rod is made of stainless steel 304. The amount of syrup poured is controlled by a cylinder or servo. Each time the type of product is changed, only the setting needs to be adjusted.

There will be induction between the pouring head and the mold plate. It will only move when the mold is sensed, ensuring the safety of the user.

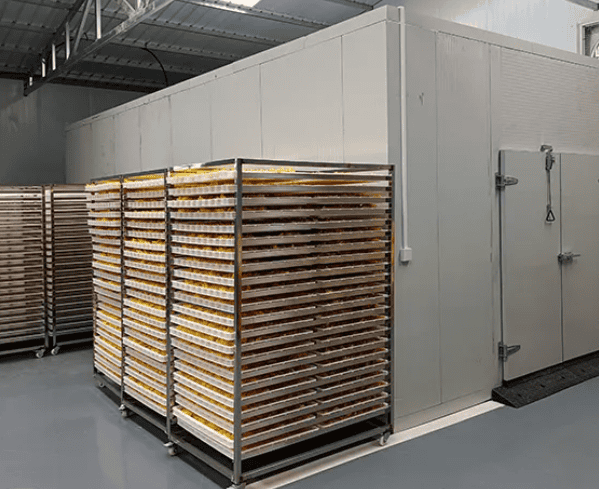

5.Drying Process

The drying room is a key equipment used to remove moisture from jelly candy during the candy production process .

It ensures that the candy reaches an ideal drying state by controlling conditions such as temperature, humidity.

And with starch line the starch will help to drying the candies until demolding.

Customers can use forklifts or cranes to help transport and reduce the labor of transportation. At the same time, qhbake can also design a fully automatic drying and conveying system.

6.De-starch

After the candy has dried, it is necessary to separate it from the starch, a process that typically generates significant waste and dust. We have created a new vacuum negative pressure powder removal design that is quieter and more space-efficient while producing less dust compared to the traditional rotary method. We have ensured that each connection is as airtight as possible, and the collected powder is transported back to the front using a screw conveyor.

The entire process of conveying and removing excess powder is automated. The candies will come out from a single direction, allowing customers to easily collect them at the exit. Alternatively, customers can send the candies to the next step in the process or to packaging via a conveyor belt.

The equipment is made of stainless steel, and the sandblasting surface can also be selected to reduce gaps and sanitary dead corners. The motors and electrical appliances are all from well-known brands such as Siemens.

Surface process

The surface of candy can exhibit various effects; some may appear crystal clear and shiny, while others may have a layer of acid sand coating them. These candies are not only visually appealing but can also provide customers with a variety of flavors. Finally, the production process requires the use of a sugar machine and an oiling machine for finishing.

Wax/Oil coating

Our oiling and waxing machine sprays edible oil and edible wax onto the surface, followed by continuous rotation of the equipment to ensure even application of the materials. The machine is designed with an internal screw mechanism that transports the product in and out, allowing for automated processing. To prioritize customer hygiene, we use stainless steel 304 in the construction of the equipment. Additionally, the machine can be reversed for alternate functions, such as cleaning.

Sukkerslibning

Sanding the white sugar on the jelly candy with fine sugar in uniform particles makes the sugar particles adhere evenly to the surface. The sugar particles on the surface of the soft candy after coating with sand increase the taste level when chewing and prevent the sugar particles from sticking together.